HYDROGEN VALVES

OMB Saleri’s main purpose is innovation.

The investments are therefore dedicated to developing new generations of increasingly innovative and competitive valves and to creating automated infrastructures for a large-scale production.

- Leader manufacturer of components for the H2 mobility →H2 storage system and fuel cell system components

- Different operating pressures 350 bar and 700 bar.

- Products for liquid hydrogen under development.

- Products approved worldwide and used on all types of vehicles (forklifts, cars, trucks, buses, trains, planes, off road vehicles) We do collaborate with the most prestigious OEMS and TIER1 worldwide.

- Components for gas transportation and industrial

1000 MIDDLE PLUG

HYDROGEN MIDDLE PLUG

DESCRIPTION

- Activation (glass bulb): 110°C

- Possibility to vent the gas

- Gas transportation trailer and fuel station

CERTIFICATIONS

- PED

350 END PLUG WITH TPRD

END PLUG WITH TEMPERATURE PRESSURE RELIEF DEVICES

DESCRIPTION

- Nominal working pressure: 350 bar

- Temperature range: -40°C / +85°C

- TPRD activation (glass bulb): 110°C or 102,7°C (± 5°C)

- Body material: Al 6061 T6 anodized

- Weight: 325 g

FEATURES

- NEW VERSION: Rotable more compact

CERTIFICATIONS

- EC79

- R134

- GB/T35544

- HPRD1

- EU535

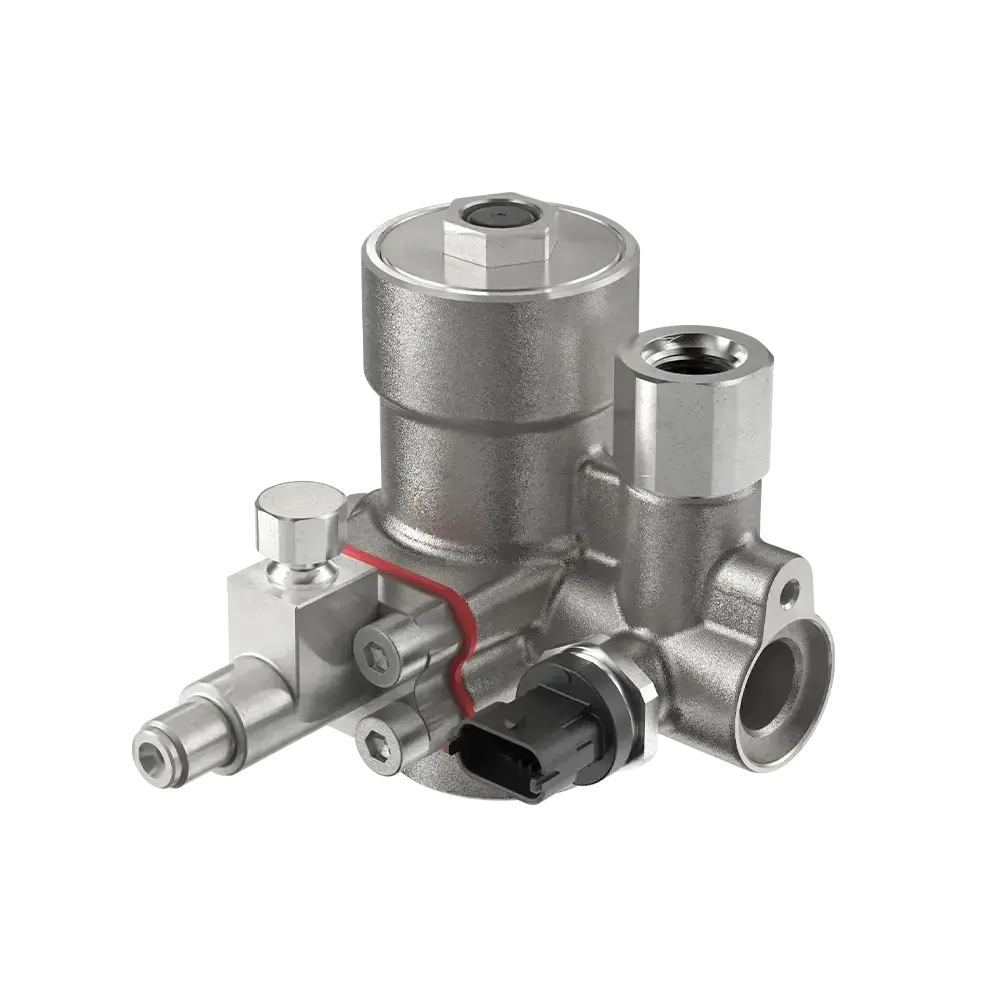

350 ERA HTV GEN 1

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

The valve is equipped with the following components:

- Inlet fitting

- Outlet port

- Single inlet/outlet port without check valve

- Solenoid valve electronically controlled;

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve);

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Tank connection

FEATURES

The valve can be requested with the following options:

- Check valve

- Excess flowvalve (flow limiter)

- Temperature sensor

- Live ports for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

- 10 micron filter (regulator confi guration)

- In-line pressure port (high pressure port)

- Pressure regulator with PRV

- Coil ATEX available

CERTIFICATIONS

- EC79

- R134

- GB/T35544

- HPRD1

- EU535

- ATEX

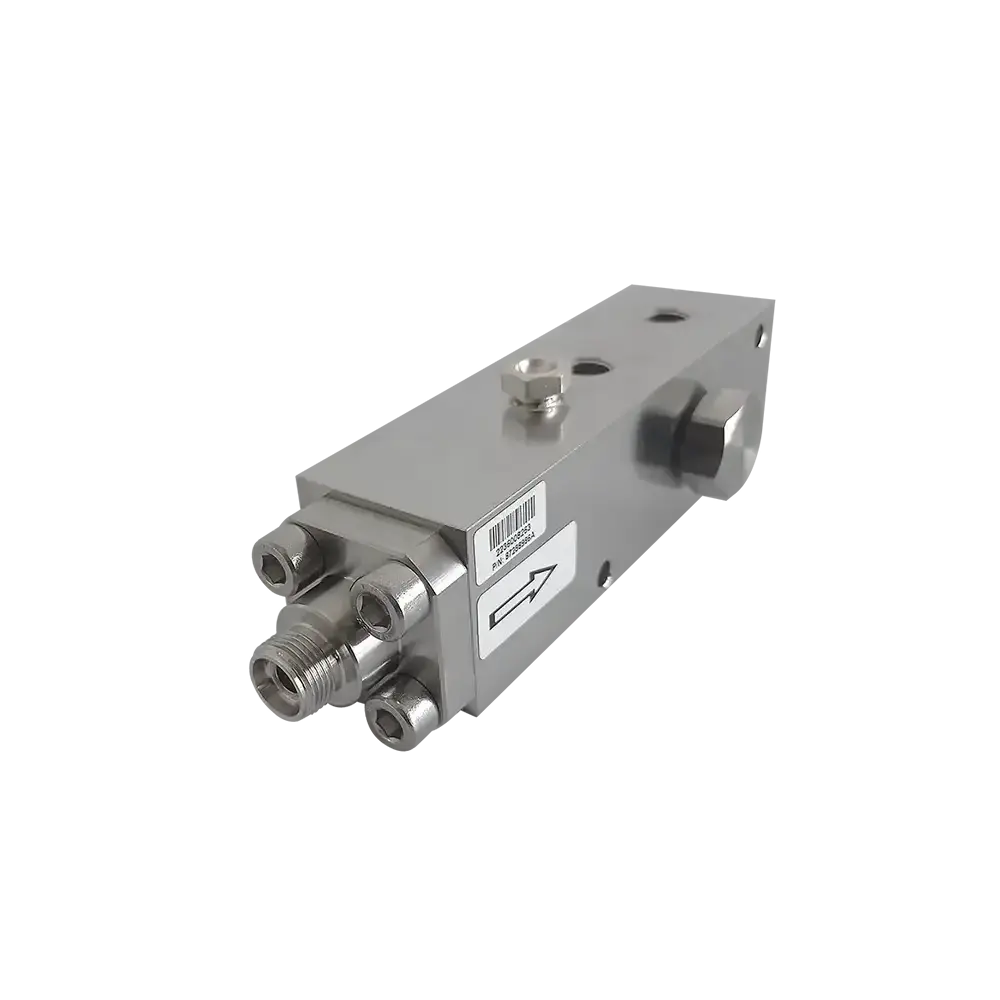

350 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

In-line check valve

CERTIFICATIONS

- EC79

- R134

350 HFR

FILLING RECEPTACLE

FEATURES

The filling receptacle 350bar is equipped with:

- 50-micron filter

- Check valve

- Dust protection cap

- SAE J2600 nozzle profile

- Max flow: 370 g/s @max deltaP 438 bar

CERTIFICATIONS

- EC79

350 HTV GEN 2

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Solenoid valve electronically controlled

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

- Live port for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

CERTIFICATIONS

- EC79

- R134

- HGV3.1

- PED

350 MIDDLE PLUG

MIDDLE PLUG WITH TEMPERATURE PRESSURE RELIEF DEVICES

DESCRIPTION

- Nominal working pressure: 350 bar

- Temperature range: -40°C / +85°C

- TPRD activation (glass bulb): 110°C or 102,7°C (± 5°C)

- Body material: AISI 316L

- Weight: 1050 g

CERTIFICATIONS

- EC79

- R134

- HGV3.1

350 MTV

MANUAL VALVE FOR GAS TRANSPORTATION & INDUSTRIAL

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

CERTIFICATIONS

- EC79

700 END PLUG GEN 2

HYDROGEN END PLUG

DESCRIPTION

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire 110°C (+/-5°C)

- Adjustable defueling port with the possibility to connect defueling pipe

- Ø orifices minimum orifice: diameter [mm] Ø 3,3

- T-senstor short or long/probe

- P-sensor

CERTIFICATIONS

- HPRD1

- R134

- EU535

700 END PLUG WITH TPRD

HYDROGEN END PLUG

DESCRIPTION

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire 110°C (+/-5°C)

- Adjustable defueling port with the possibility to connect defueling pipe

- Ø Orifices minimum orifice: diameter [mm] Ø2

CERTIFICATIONS

- EC79

- R134

- EU535

- HPRD1

- KHK

700 END PLUG WITHOUT TPRD

HYDROGEN END PLUG

DESCRIPTION

- Plug to close the tank

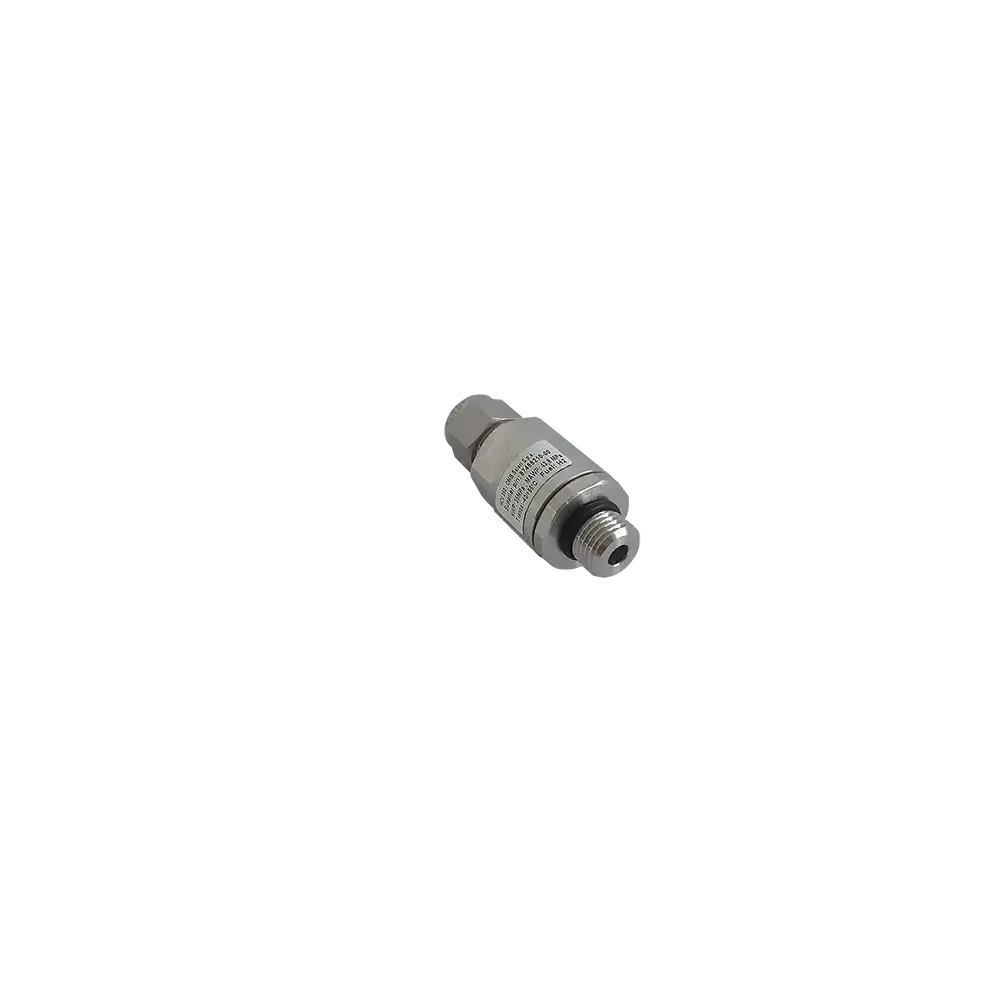

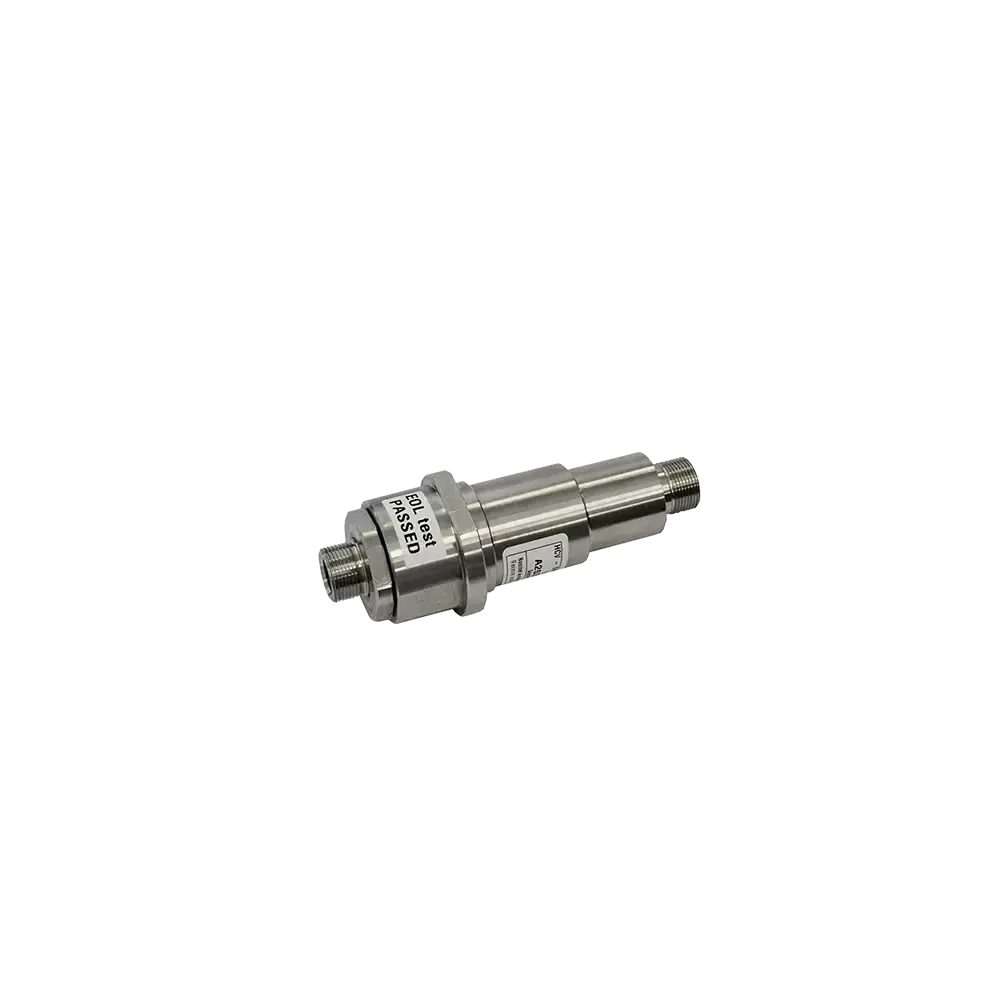

700 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

- 10 Microns filter protection

- In-line check valve

CERTIFICATIONS

- EC79

700 HFR

HYDROGEN FILLING RECEPTACLE

DESCRIPTION

- H70 Hydrogen receptacle shape according to: SAE J2600 / ISO 17268

- 10 microns Filter protection

- Possibility to install IR emitter

- Dust cap options

- Dedicated bracket to assemble the valve to the chassis

CERTIFICATIONS

- EC79

700 MIDDLE PLUG

HYDROGEN MIDDLE PLUG

DESCRIPTION

- Activation (glass bulb): 110°C

- Possibility to vent the gas

CERTIFICATIONS

- R134

- EU535

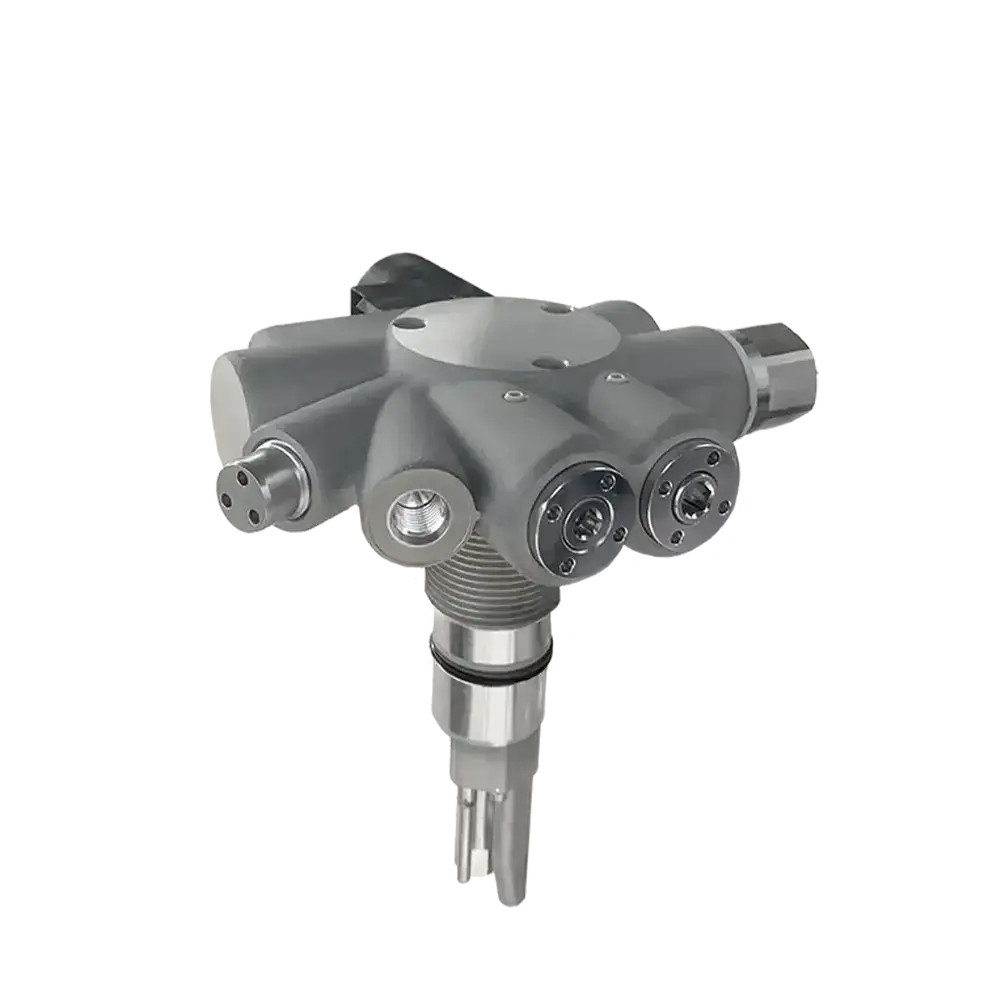

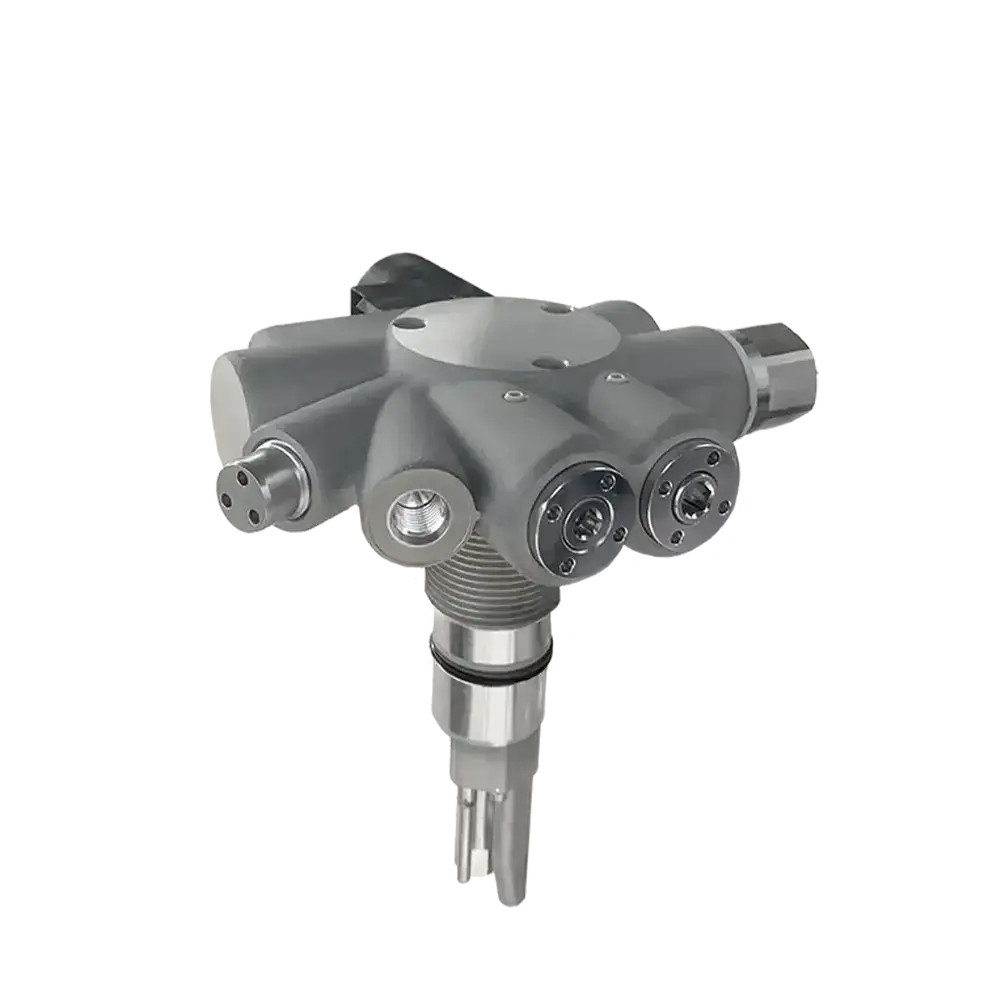

700 OTV GEN 2

On Tank Valve

DESCRIPTION

OMB 700 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use. The valve is equipped with the following components:

- Single inlet/outlet port

- Improved solenoid valve endurance compare to Gen1

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Two Filters 10 micron

- Fueling Check valve

- Temperature sensor

- Excess flow valve (flow limiter)

- Pressure Port

- Port for Middle TPRD

CERTIFICATIONS

- EC79

- R134

- EU535

- HGV3.1

- HPRD1

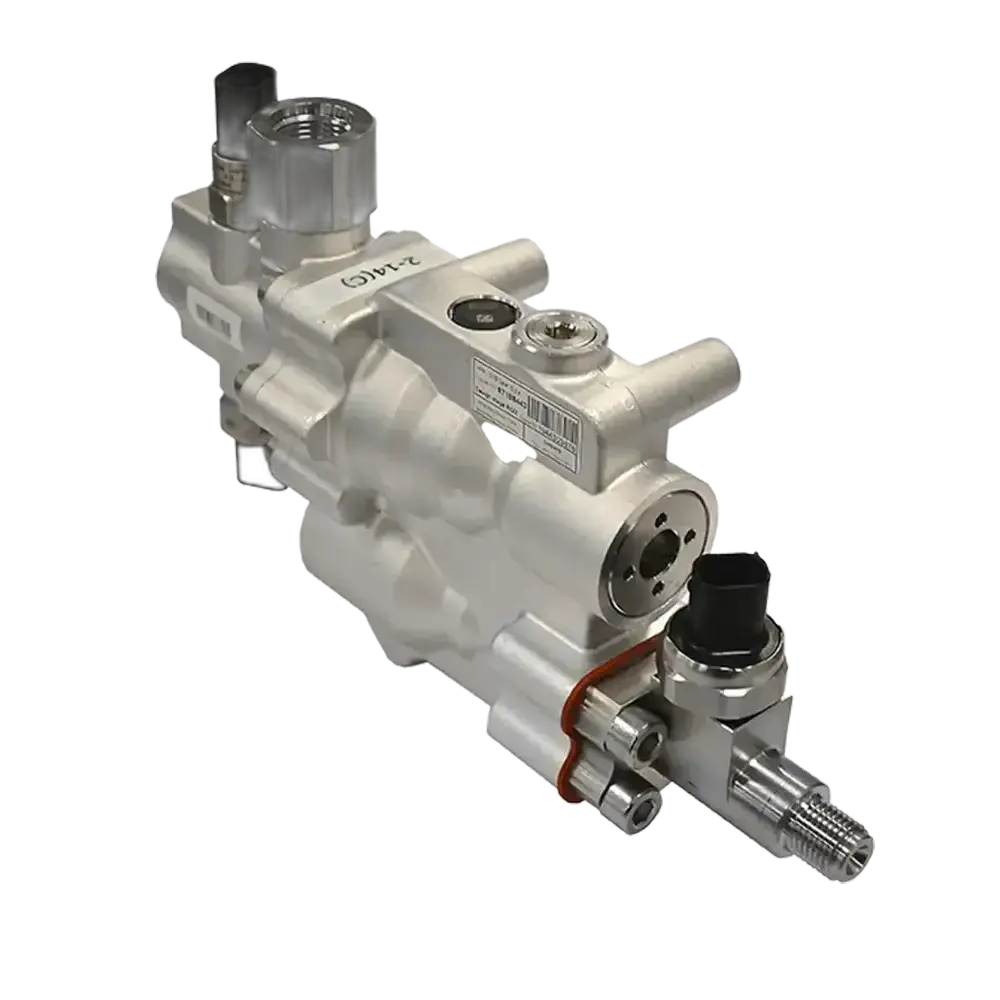

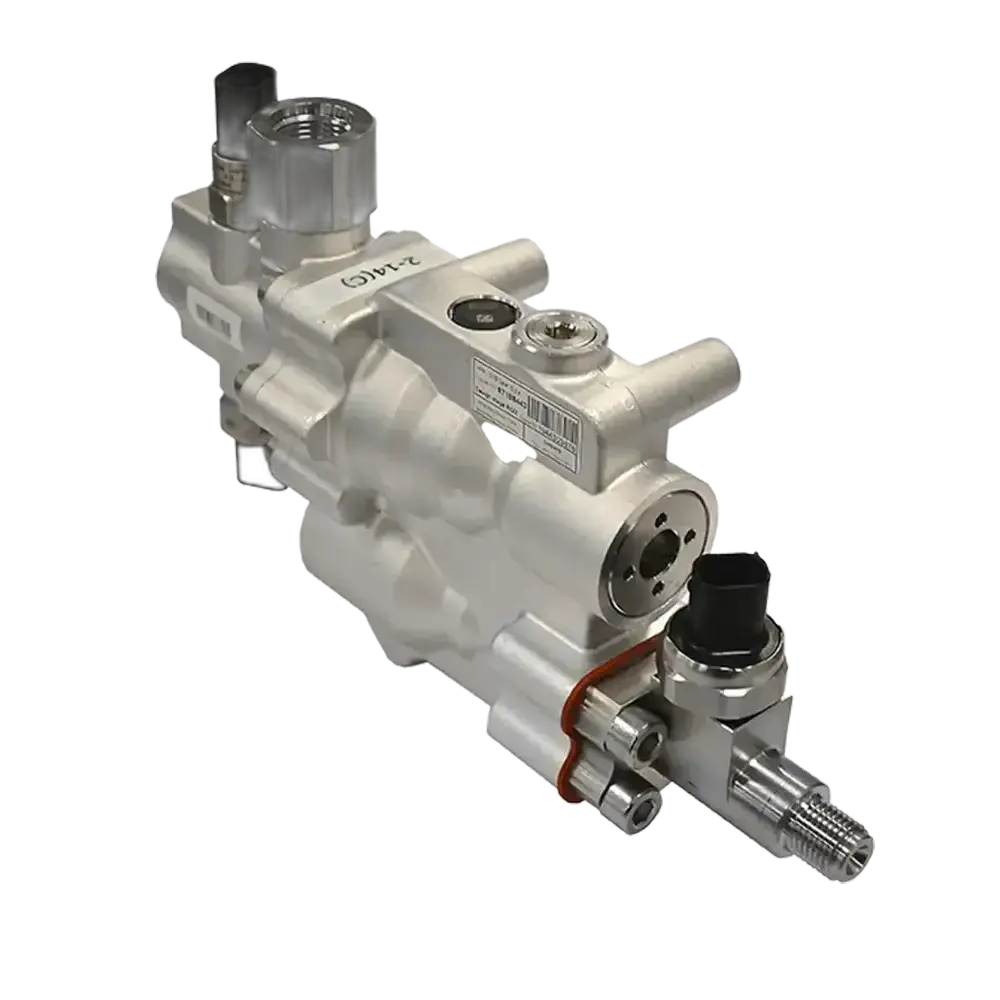

700/350 HPR

HYDROGEN PRESSURE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical double stage regulator designed for fuel cell applications with the following components integrated:

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

FEATURES

The HPR can be requested with the following options:

- High Pressure sensors

- Low Pressure sensors (up to 2)

- Low Pressure Service Valve

- Outlet regulated pressure from 8bar to 16bar

- Inlet 700bar: Voss / Autoclave OD 3/8

- Inlet 350bar: SAEJ 1926

- PRV: customizable activation

- Possibility to install high and low-pressure sensor

CERTIFICATIONS

- EC79

- PED

700/350 HPR1s

HYDROGEN SINGLE STAGE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical single stage regulator designed for light duties hydrogen applications with a compact shape, leightweight and cost effective

FEATURES

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

- Possibility to integrate high and low pressure sensors

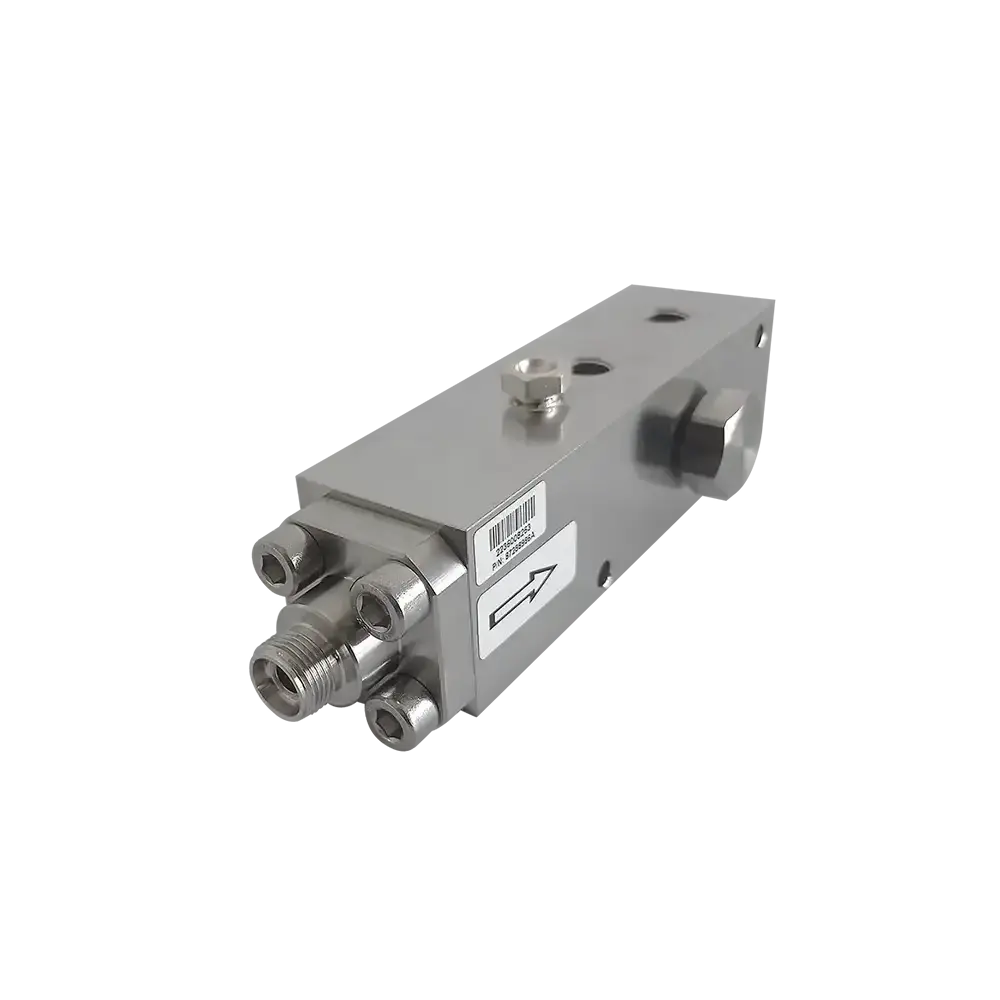

700/350 MANIFOLD

DESCRIPTION

Multifunctional manifold, with the possibility to integrate:

- Inlet filter 10/50 microns

- Inlet check valve

- Gas dstribution to the tanks

- Gas distribution to the regulator

- Pressure sensors

CERTIFICATIONS

- EC79

700/350 SMA

EXTERNAL WIRE TPRD

DESCRIPTION

The SMA-TPRD is an innovative thermal relief device aimed at increasing the safety system by reducing complexity and cost. It is based on a double effect ignition technology which does alloy to detect thermal threats over the entire lenght of the tanks. In event of fire, the quickignition and the fast discharge of the SMA-TPRD reduce the risk of fuel tank faults

FEATURES

- Long distance thermal safety device

- Nominal working pressure: 350bar 700bar

- Temperature range: -40°C / +85°CTPRD

- Activation (glass bulb): 110°C (± 5°C)

- Body material: AISI 316L

- Double triggering technology

- Pipe length from 400 mm up to 3920mm

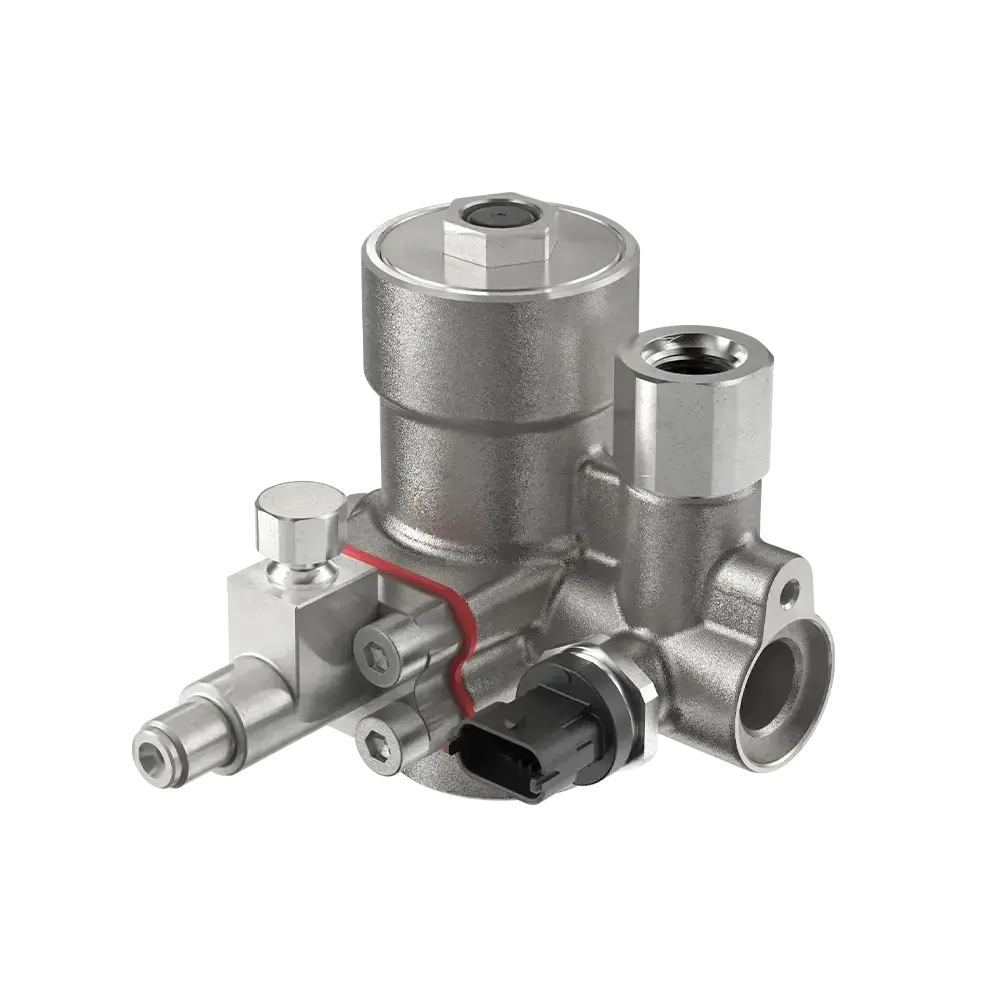

ADV & APV

ANODE DRAIN & PURGE VALVE

DESCRIPTION

- Normally closed valve

- Cartridge solution or on body or integrate in the AWS

- Main Gasket material: EPDM

- Relative humidity: From 0 to 100%

- IP protection: IP5K4 for electrical parts

- Opening response time: < 100 ms

- Closing response time: < 100 ms

- Working fluids: Hydrogen, Air, Helium, Nitrogen, Water(pH4-7), Vapor, Ice, Hydrofluoric acid, Hydrogen peroxide

FEATURES

The valve can be requested with the following options:

- Heaters (PTC or NTC)

- Fastening clip

- Dedicated connector

- Transil or thermal control in the coil

- Integration on the Water separator

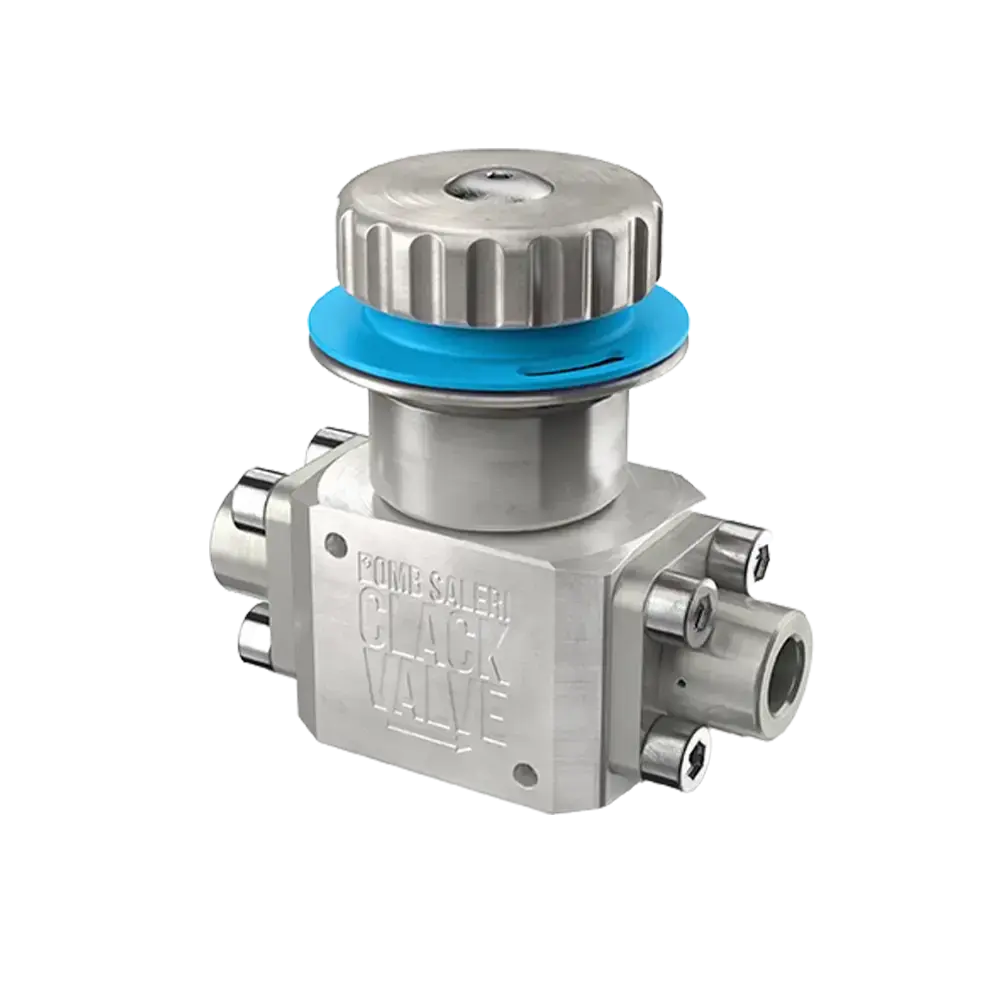

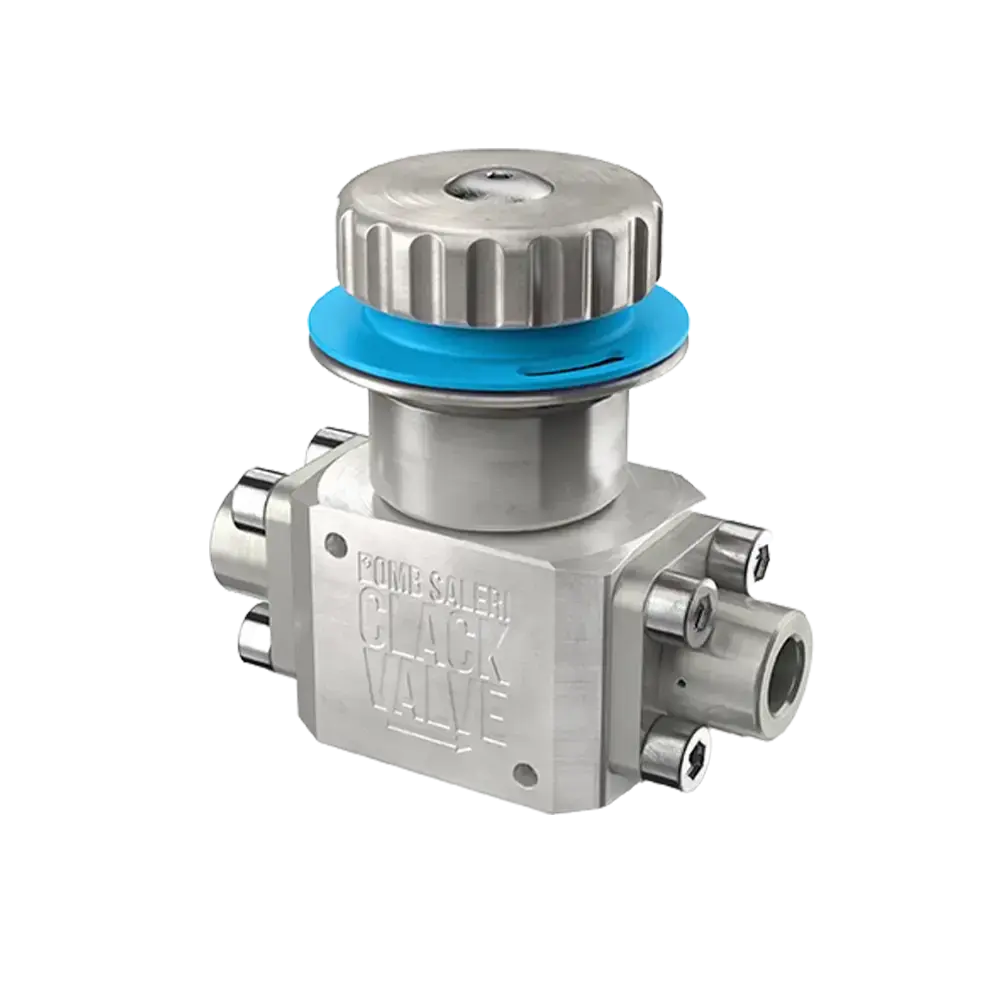

CLACK VALVE

MANUAL VALVE FOR GAS TRANSPORTATION & INDUSTRIAL

DESCRIPTION

The clack valve is an innovative needle manual valve designed to withstand high pressure and high flow according to the main gas transportation market demands.

The ergonomic handle allows the opening and closing with only one turn and a very low torque.

This valve integrates a visual indicator and an innovation patented solution with anti-overtorque system that avoids improper usage in the field.

The needle valve technology allows a progressive opening avoids the shocks in the system.

FEATURES

- NWP: 560 bar (upgradable to 700bar)

- H2 compatible

- Needle manual valve

- InLine connection (customizable)

- HOLE Ø13mm

- Less than 1 turn to open and close

- Open/close indicator

- Open/close torque at the opening: max 3 Nm

- Total weight estimation in SS: 3500 gr.

LPRV

LOW PRESSURE RELIEF VALVE

DESCRIPTION

The pressure relief valve is a safety component which activates in case of overpressure, venting the gas from its outlet.

SOV

SHUT OFF VALVE

DESCRIPTION

Sov with manual valve

On/off safety device

Possible configuration 12 / 24v.

STAND ALONE FILTER

DESCRIPTION

- 10 Micron mesh filter

- Inlet 3/4” - 16 UNF - 2A

- Outlet double ferrule connection for pipe OD 1/2”

- Temp. -40°C , +65°C

- Max working pressure 20 bar G

- Nominal working pressure 9.7 bar G

WATER SEPARATOR

DESCRIPTION

OMB has developed a water separator with anode anddrain valves and level sensor integrated.

The integration allows to the final user to have a plug and play system reducing the assembly time.

The water separator is characterized by a water separation efficiency higher than 95%.

1000 MIDDLE PLUG

HYDROGEN MIDDLE PLUG

DESCRIPTION

- Activation (glass bulb): 110°C

- Possibility to vent the gas

- Gas transportation trailer and fuel station

CERTIFICATIONS

- PED

350 END PLUG WITH TPRD

END PLUG WITH TEMPERATURE PRESSURE RELIEF DEVICES

DESCRIPTION

- Nominal working pressure: 350 bar

- Temperature range: -40°C / +85°C

- TPRD activation (glass bulb): 110°C or 102,7°C (± 5°C)

- Body material: Al 6061 T6 anodized

- Weight: 325 g

FEATURES

- NEW VERSION: Rotable more compact

CERTIFICATIONS

- EC79

- R134

- GB/T35544

- HPRD1

- EU535

350 ERA HTV GEN 1

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

The valve is equipped with the following components:

- Inlet fitting

- Outlet port

- Single inlet/outlet port without check valve

- Solenoid valve electronically controlled;

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve);

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Tank connection

FEATURES

The valve can be requested with the following options:

- Check valve

- Excess flowvalve (flow limiter)

- Temperature sensor

- Live ports for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

- 10 micron filter (regulator confi guration)

- In-line pressure port (high pressure port)

- Pressure regulator with PRV

- Coil ATEX available

CERTIFICATIONS

- EC79

- R134

- GB/T35544

- HPRD1

- EU535

- ATEX

350 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

In-line check valve

CERTIFICATIONS

- EC79

- R134

350 HFR

FILLING RECEPTACLE

FEATURES

The filling receptacle 350bar is equipped with:

- 50-micron filter

- Check valve

- Dust protection cap

- SAE J2600 nozzle profile

- Max flow: 370 g/s @max deltaP 438 bar

CERTIFICATIONS

- EC79

350 HTV GEN 2

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Solenoid valve electronically controlled

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

- Live port for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

CERTIFICATIONS

- EC79

- R134

- HGV3.1

- PED

350 MIDDLE PLUG

MIDDLE PLUG WITH TEMPERATURE PRESSURE RELIEF DEVICES

DESCRIPTION

- Nominal working pressure: 350 bar

- Temperature range: -40°C / +85°C

- TPRD activation (glass bulb): 110°C or 102,7°C (± 5°C)

- Body material: AISI 316L

- Weight: 1050 g

CERTIFICATIONS

- EC79

- R134

- HGV3.1

350 MTV

MANUAL VALVE FOR GAS TRANSPORTATION & INDUSTRIAL

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

CERTIFICATIONS

- EC79

700 END PLUG GEN 2

HYDROGEN END PLUG

DESCRIPTION

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire 110°C (+/-5°C)

- Adjustable defueling port with the possibility to connect defueling pipe

- Ø orifices minimum orifice: diameter [mm] Ø 3,3

- T-senstor short or long/probe

- P-sensor

CERTIFICATIONS

- HPRD1

- R134

- EU535

700 END PLUG WITH TPRD

HYDROGEN END PLUG

DESCRIPTION

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire 110°C (+/-5°C)

- Adjustable defueling port with the possibility to connect defueling pipe

- Ø Orifices minimum orifice: diameter [mm] Ø2

CERTIFICATIONS

- EC79

- R134

- EU535

- HPRD1

- KHK

700 END PLUG WITHOUT TPRD

HYDROGEN END PLUG

DESCRIPTION

- Plug to close the tank

700 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

- 10 Microns filter protection

- In-line check valve

CERTIFICATIONS

- EC79

700 HFR

HYDROGEN FILLING RECEPTACLE

DESCRIPTION

- H70 Hydrogen receptacle shape according to: SAE J2600 / ISO 17268

- 10 microns Filter protection

- Possibility to install IR emitter

- Dust cap options

- Dedicated bracket to assemble the valve to the chassis

CERTIFICATIONS

- EC79

700 MIDDLE PLUG

HYDROGEN MIDDLE PLUG

DESCRIPTION

- Activation (glass bulb): 110°C

- Possibility to vent the gas

CERTIFICATIONS

- R134

- EU535

700 OTV GEN 2

On Tank Valve

DESCRIPTION

OMB 700 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use. The valve is equipped with the following components:

- Single inlet/outlet port

- Improved solenoid valve endurance compare to Gen1

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Two Filters 10 micron

- Fueling Check valve

- Temperature sensor

- Excess flow valve (flow limiter)

- Pressure Port

- Port for Middle TPRD

CERTIFICATIONS

- EC79

- R134

- EU535

- HGV3.1

- HPRD1

700/350 HPR

HYDROGEN PRESSURE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical double stage regulator designed for fuel cell applications with the following components integrated:

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

FEATURES

The HPR can be requested with the following options:

- High Pressure sensors

- Low Pressure sensors (up to 2)

- Low Pressure Service Valve

- Outlet regulated pressure from 8bar to 16bar

- Inlet 700bar: Voss / Autoclave OD 3/8

- Inlet 350bar: SAEJ 1926

- PRV: customizable activation

- Possibility to install high and low-pressure sensor

CERTIFICATIONS

- EC79

- PED

700/350 HPR1s

HYDROGEN SINGLE STAGE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical single stage regulator designed for light duties hydrogen applications with a compact shape, leightweight and cost effective

FEATURES

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

- Possibility to integrate high and low pressure sensors

700/350 MANIFOLD

DESCRIPTION

Multifunctional manifold, with the possibility to integrate:

- Inlet filter 10/50 microns

- Inlet check valve

- Gas dstribution to the tanks

- Gas distribution to the regulator

- Pressure sensors

CERTIFICATIONS

- EC79

700/350 SMA

EXTERNAL WIRE TPRD

DESCRIPTION

The SMA-TPRD is an innovative thermal relief device aimed at increasing the safety system by reducing complexity and cost. It is based on a double effect ignition technology which does alloy to detect thermal threats over the entire lenght of the tanks. In event of fire, the quickignition and the fast discharge of the SMA-TPRD reduce the risk of fuel tank faults

FEATURES

- Long distance thermal safety device

- Nominal working pressure: 350bar 700bar

- Temperature range: -40°C / +85°CTPRD

- Activation (glass bulb): 110°C (± 5°C)

- Body material: AISI 316L

- Double triggering technology

- Pipe length from 400 mm up to 3920mm

ADV & APV

ANODE DRAIN & PURGE VALVE

DESCRIPTION

- Normally closed valve

- Cartridge solution or on body or integrate in the AWS

- Main Gasket material: EPDM

- Relative humidity: From 0 to 100%

- IP protection: IP5K4 for electrical parts

- Opening response time: < 100 ms

- Closing response time: < 100 ms

- Working fluids: Hydrogen, Air, Helium, Nitrogen, Water(pH4-7), Vapor, Ice, Hydrofluoric acid, Hydrogen peroxide

FEATURES

The valve can be requested with the following options:

- Heaters (PTC or NTC)

- Fastening clip

- Dedicated connector

- Transil or thermal control in the coil

- Integration on the Water separator

CLACK VALVE

MANUAL VALVE FOR GAS TRANSPORTATION & INDUSTRIAL

DESCRIPTION

The clack valve is an innovative needle manual valve designed to withstand high pressure and high flow according to the main gas transportation market demands.

The ergonomic handle allows the opening and closing with only one turn and a very low torque.

This valve integrates a visual indicator and an innovation patented solution with anti-overtorque system that avoids improper usage in the field.

The needle valve technology allows a progressive opening avoids the shocks in the system.

FEATURES

- NWP: 560 bar (upgradable to 700bar)

- H2 compatible

- Needle manual valve

- InLine connection (customizable)

- HOLE Ø13mm

- Less than 1 turn to open and close

- Open/close indicator

- Open/close torque at the opening: max 3 Nm

- Total weight estimation in SS: 3500 gr.

LPRV

LOW PRESSURE RELIEF VALVE

DESCRIPTION

The pressure relief valve is a safety component which activates in case of overpressure, venting the gas from its outlet.

SOV

SHUT OFF VALVE

DESCRIPTION

Sov with manual valve

On/off safety device

Possible configuration 12 / 24v.

STAND ALONE FILTER

DESCRIPTION

- 10 Micron mesh filter

- Inlet 3/4” - 16 UNF - 2A

- Outlet double ferrule connection for pipe OD 1/2”

- Temp. -40°C , +65°C

- Max working pressure 20 bar G

- Nominal working pressure 9.7 bar G

WATER SEPARATOR

DESCRIPTION

OMB has developed a water separator with anode anddrain valves and level sensor integrated.

The integration allows to the final user to have a plug and play system reducing the assembly time.

The water separator is characterized by a water separation efficiency higher than 95%.