AEROSPACE DIVISION

OMB Saleri is today an excellence in development and manufacturing of components for green mobility (mainly hydrogen application).

The decision to take the challenges of the aerospace market was driven by the company’s vision toward product innovation.

OMB Aerospace dpt is able to evaluate and assess customers specifications and to codevelop new innovative items.

The processes to manage ambitious projects in aerospace is supported by a reliable business planning procedure, by the availability of laboratories to carry-out trials and is secured by OMB internal continuous improvement approach.

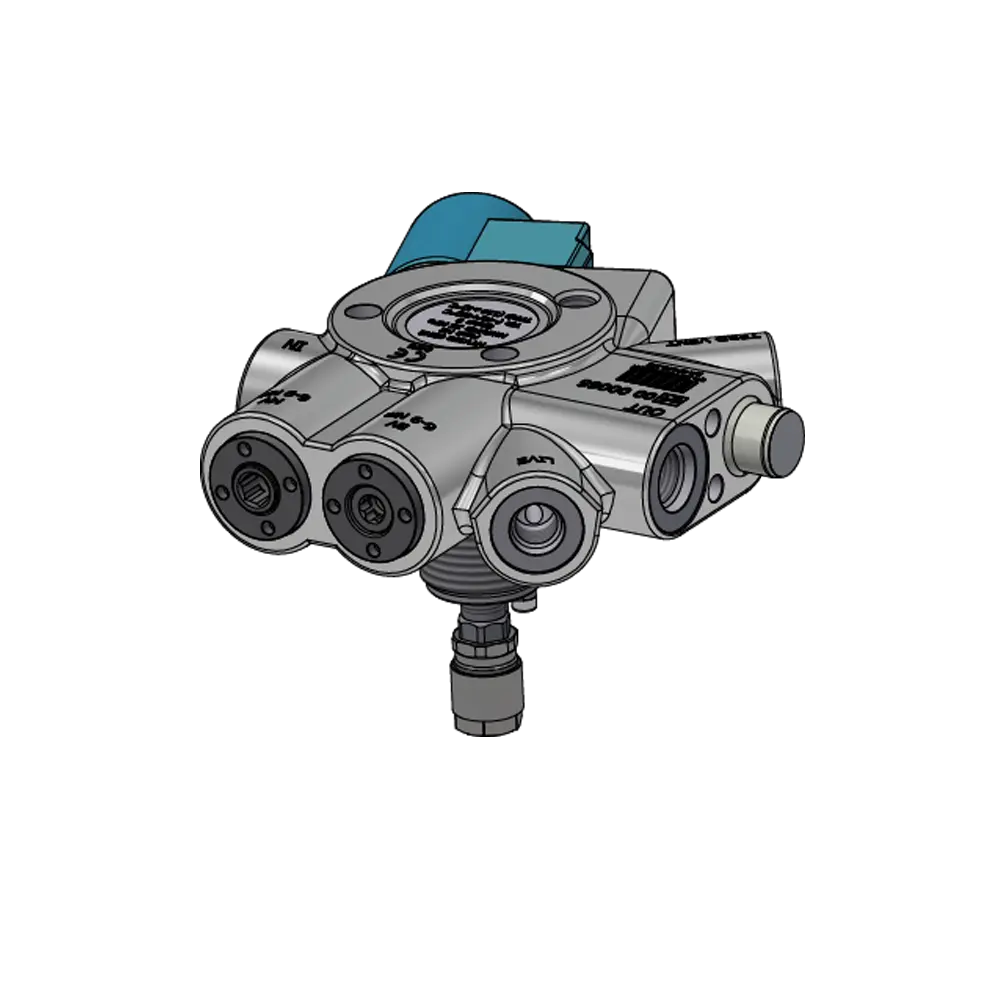

350 HTV GEN 2

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Solenoid valve electronically controlled

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

- Live port for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

CERTIFICATIONS

- EC79

- R134

- HGV3.1

- PED

700 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

- 10 Microns filter protection

- In-line check valve

CERTIFICATIONS

- EC79

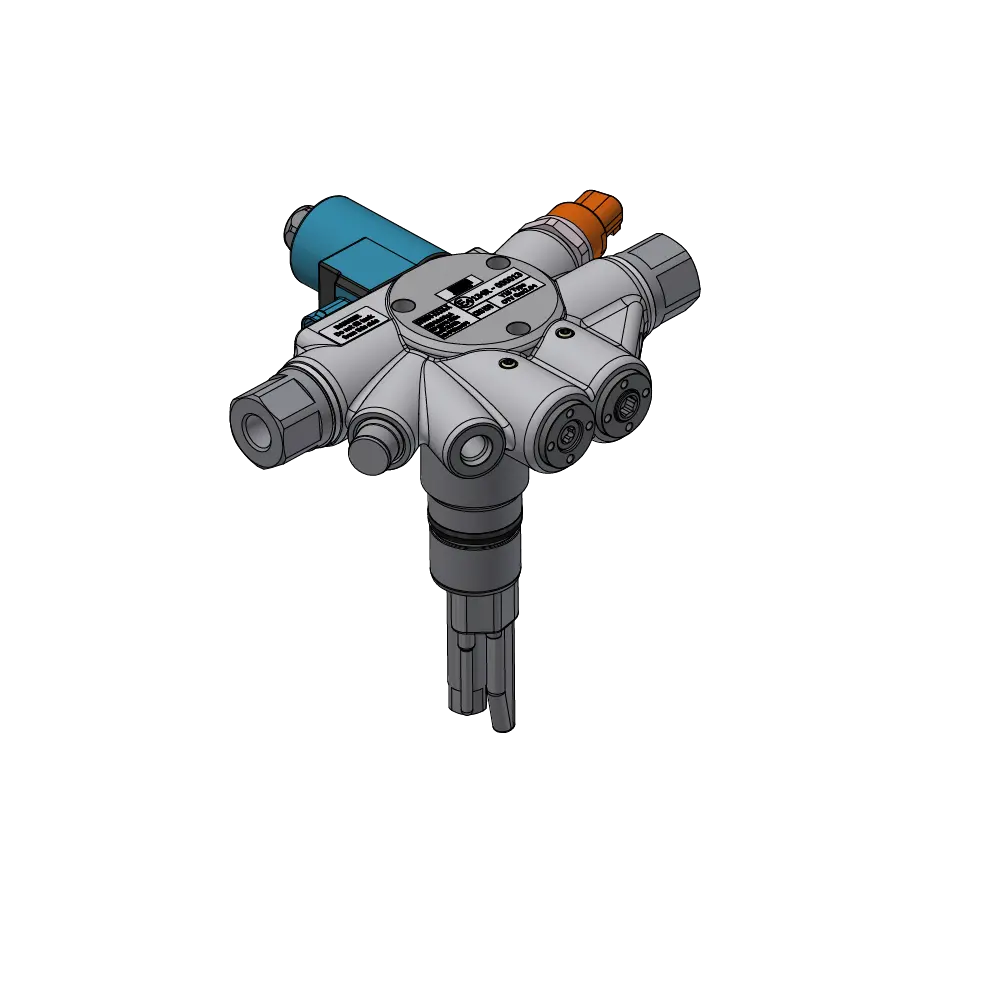

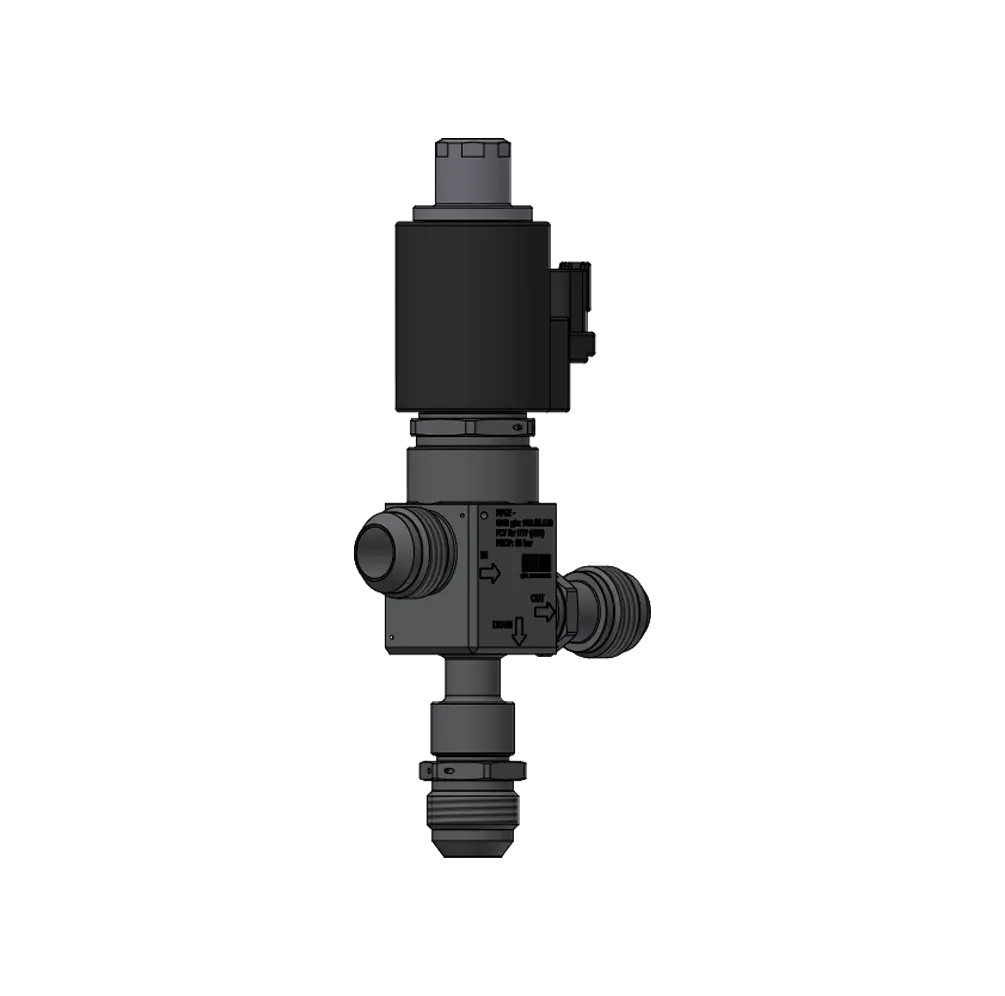

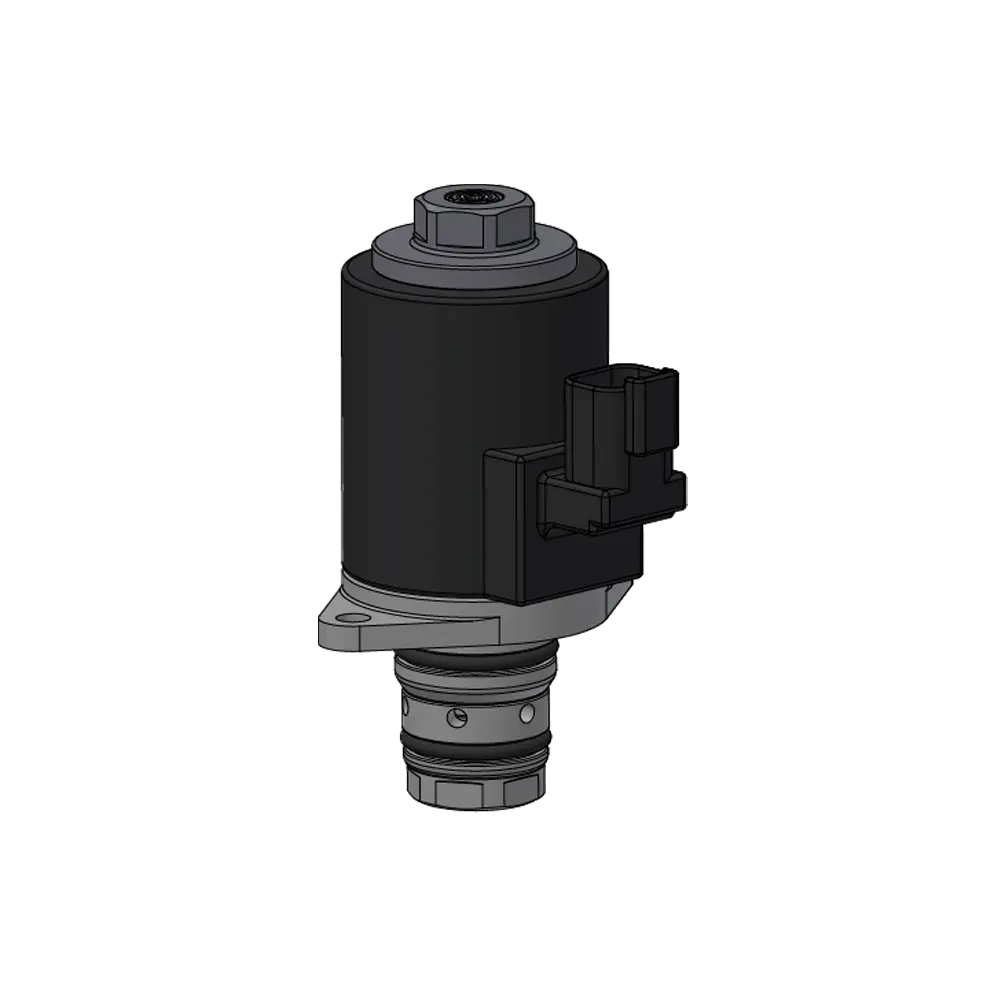

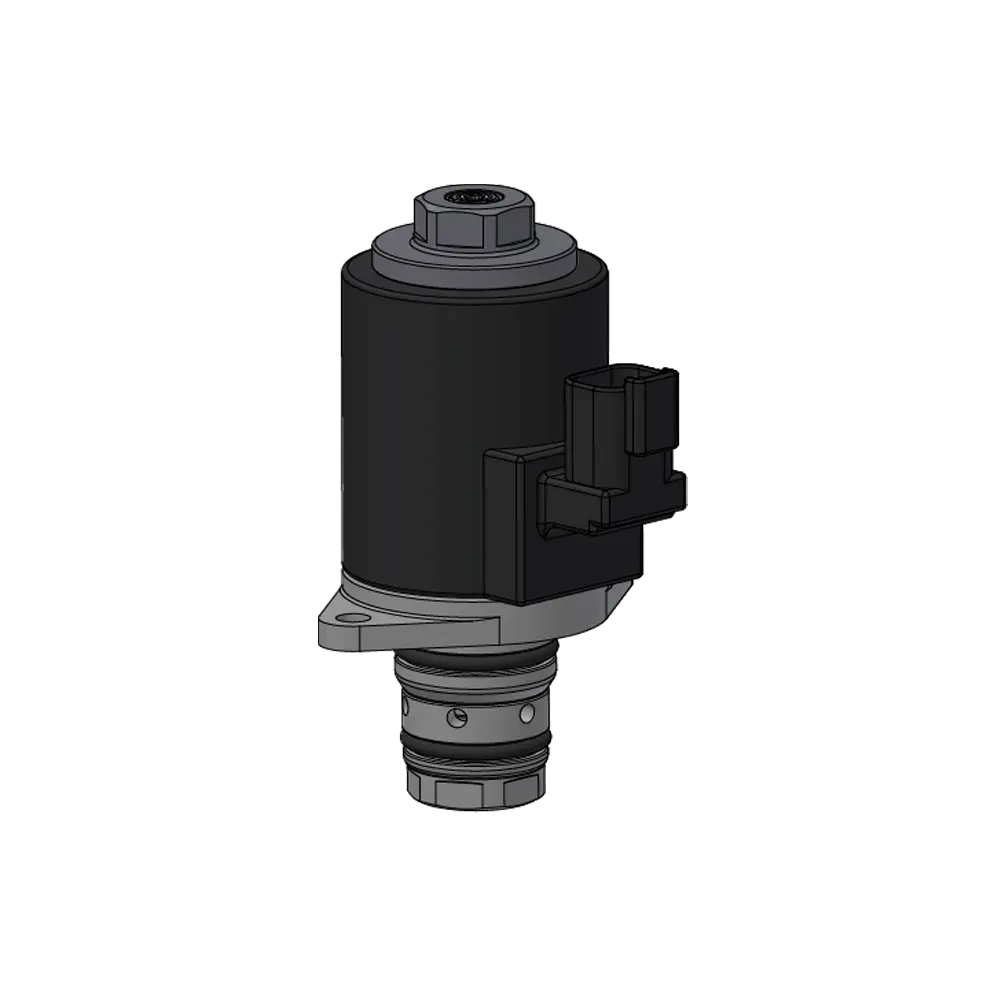

700 OTV GEN 2

On Tank Valve

DESCRIPTION

OMB 700 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use. The valve is equipped with the following components:

- Single inlet/outlet port

- Improved solenoid valve endurance compare to Gen1

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Two Filters 10 micron

- Fueling Check valve

- Temperature sensor

- Excess flow valve (flow limiter)

- Pressure Port

- Port for Middle TPRD

CERTIFICATIONS

- EC79

- R134

- EU535

- HGV3.1

- HPRD1

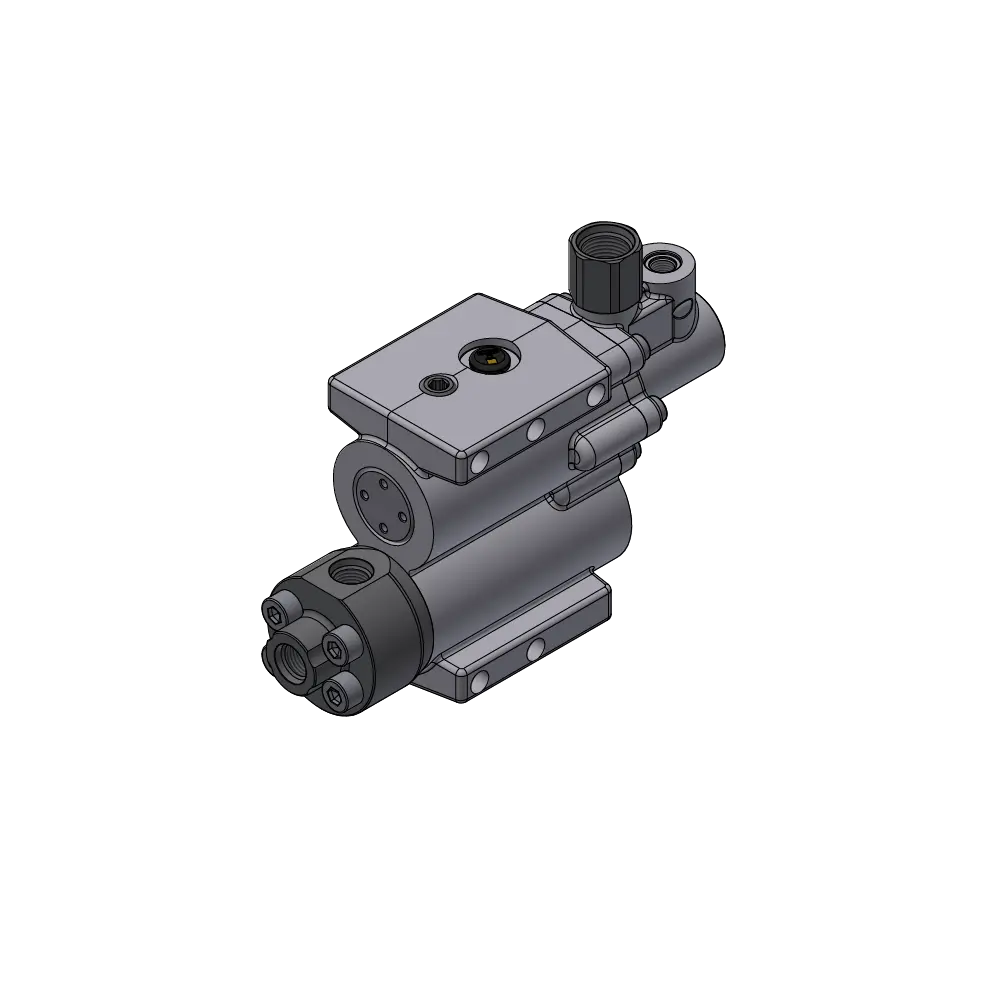

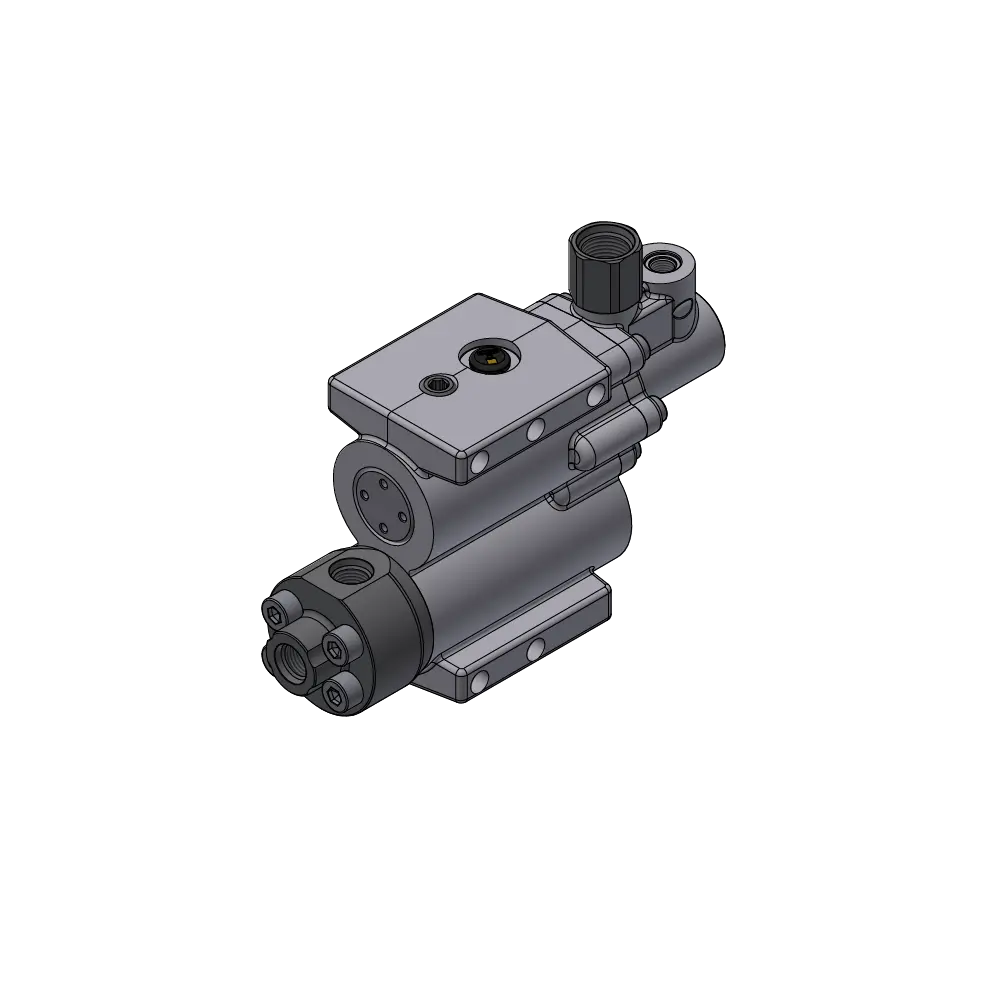

700/350 HPR

HYDROGEN PRESSURE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical double stage regulator designed for fuel cell applications with the following components integrated:

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

FEATURES

The HPR can be requested with the following options:

- High Pressure sensors

- Low Pressure sensors (up to 2)

- Low Pressure Service Valve

- Outlet regulated pressure from 8bar to 16bar

- Inlet 700bar: Voss / Autoclave OD 3/8

- Inlet 350bar: SAEJ 1926

- PRV: customizable activation

- Possibility to install high and low-pressure sensor

CERTIFICATIONS

- EC79

- PED

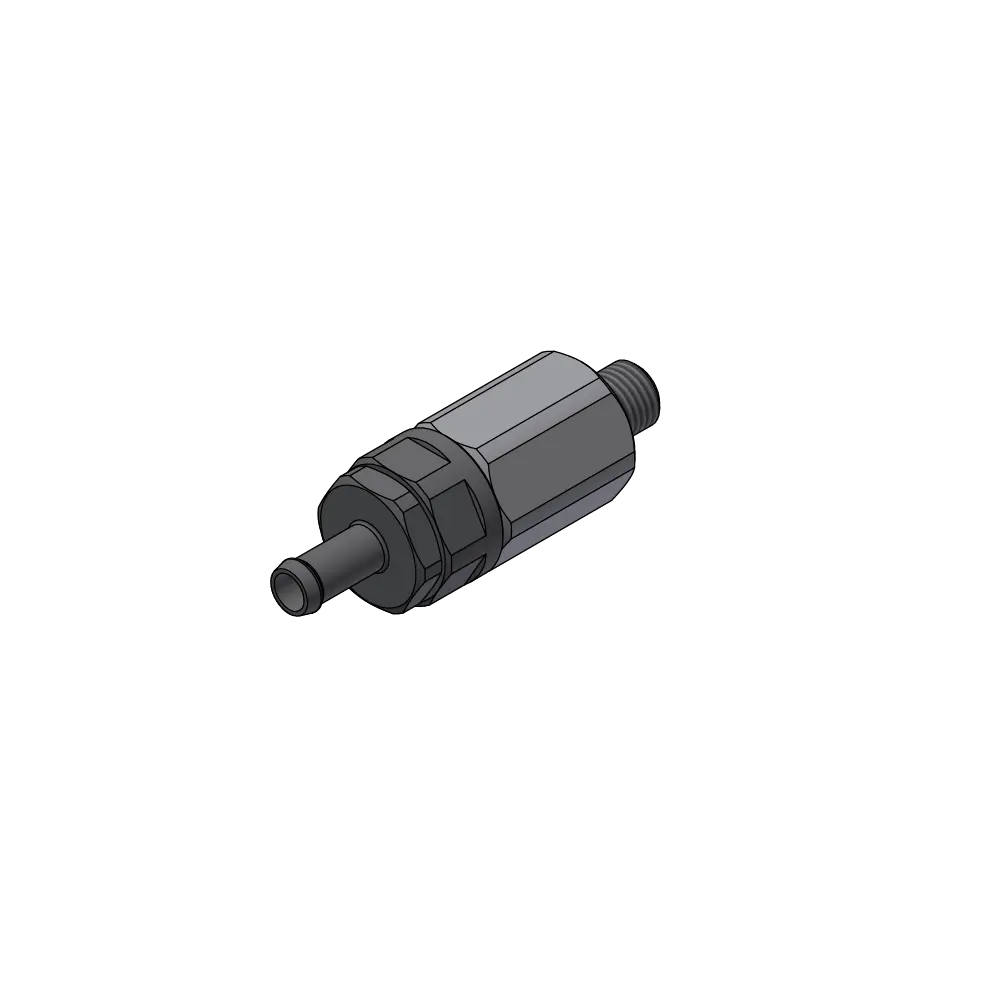

COV

DESCRIPTION

mechanical valve that opens and closes under the action of the upstream pressure.

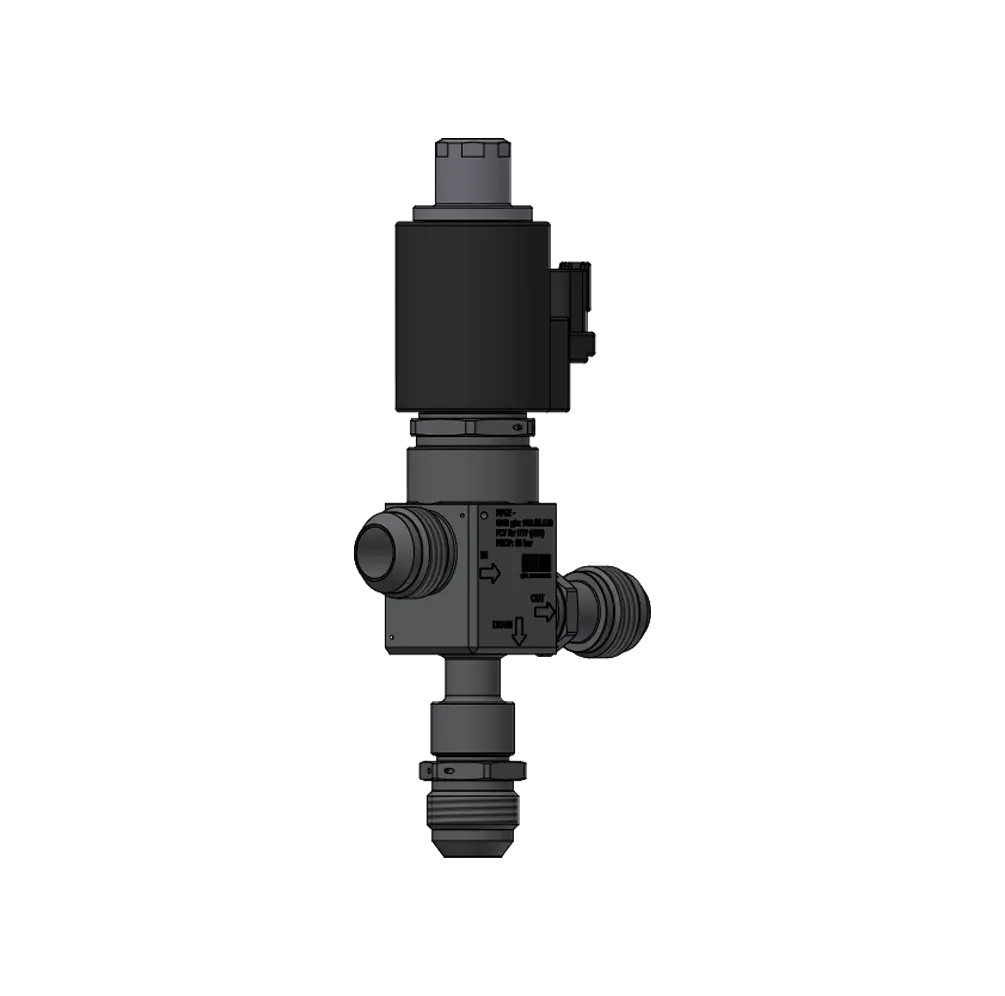

FCV

DESCRIPTION

3-way solenoid valve electrically actuated.

FIL

DESCRIPTION

Filter designed to protect the downstream items from contamination.

GPR

DESCRIPTION

mechanical single stage pressure regulator with inlet filter.

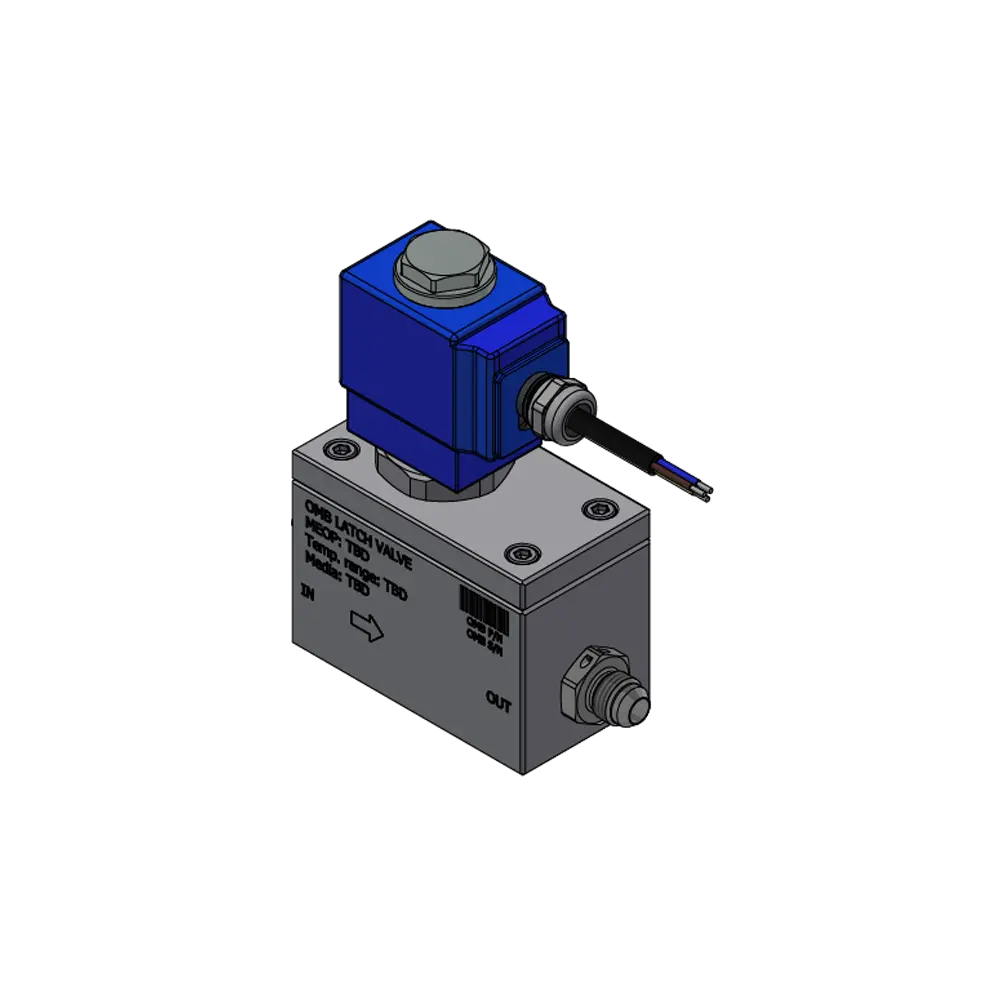

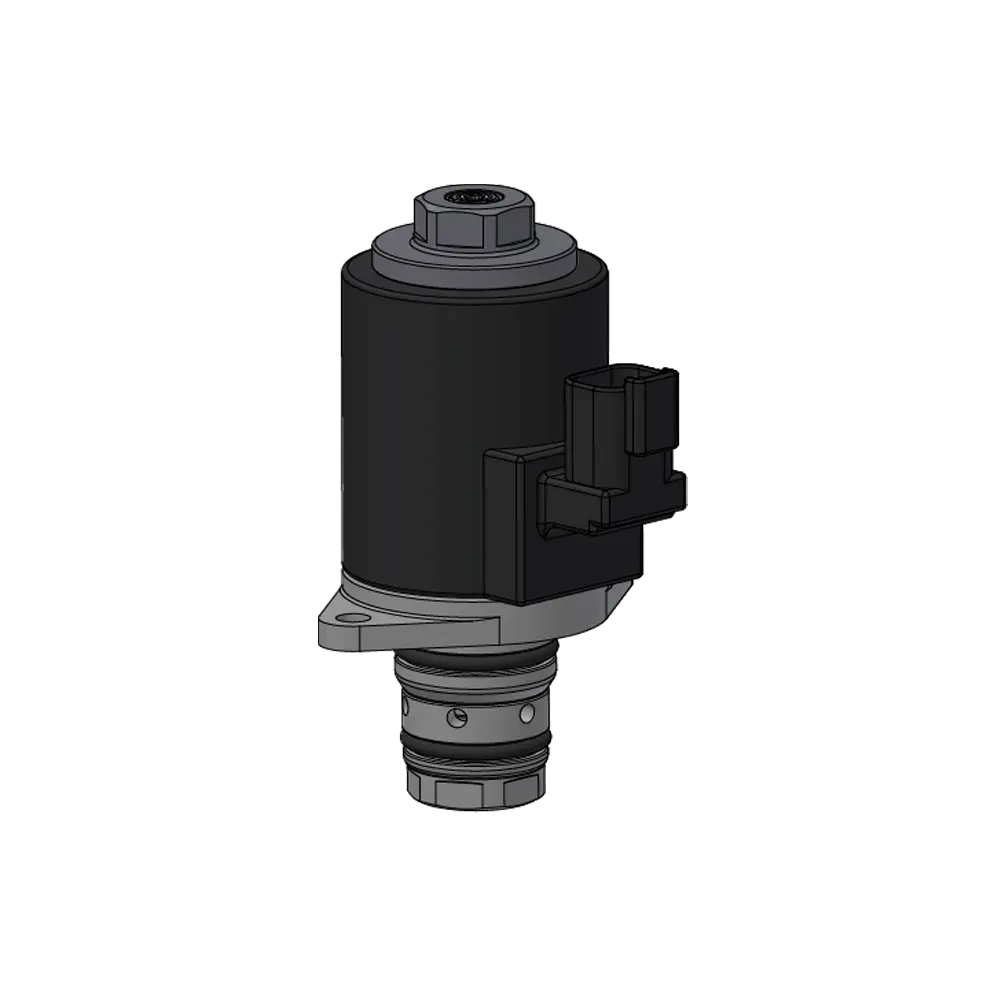

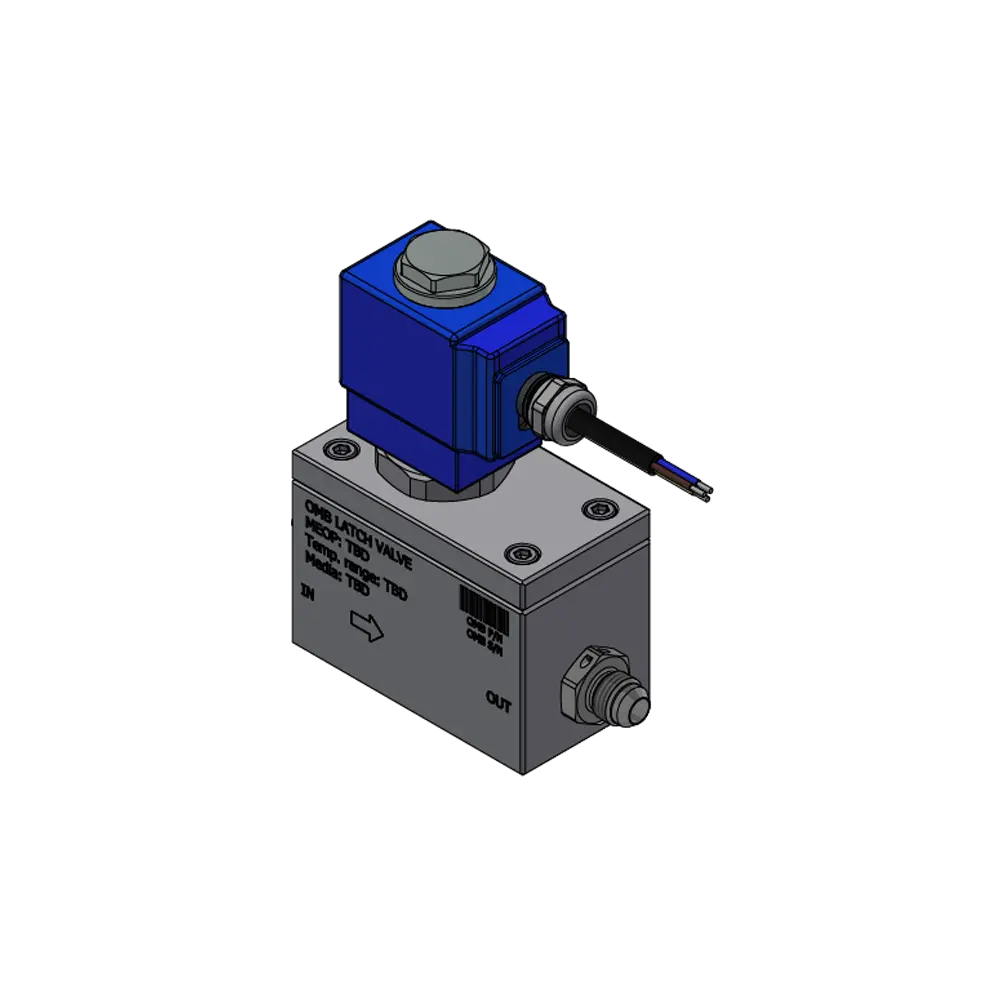

LATCH VALVE

DESCRIPTION

bi-stable solenoid valve that opens and closes upon electrical command and keep the open/close also without the electrical signal.

LPRV

LOW PRESSURE RELIEF VALVE

DESCRIPTION

The pressure relief valve is a safety component which activates in case of overpressure, venting the gas from its outlet.

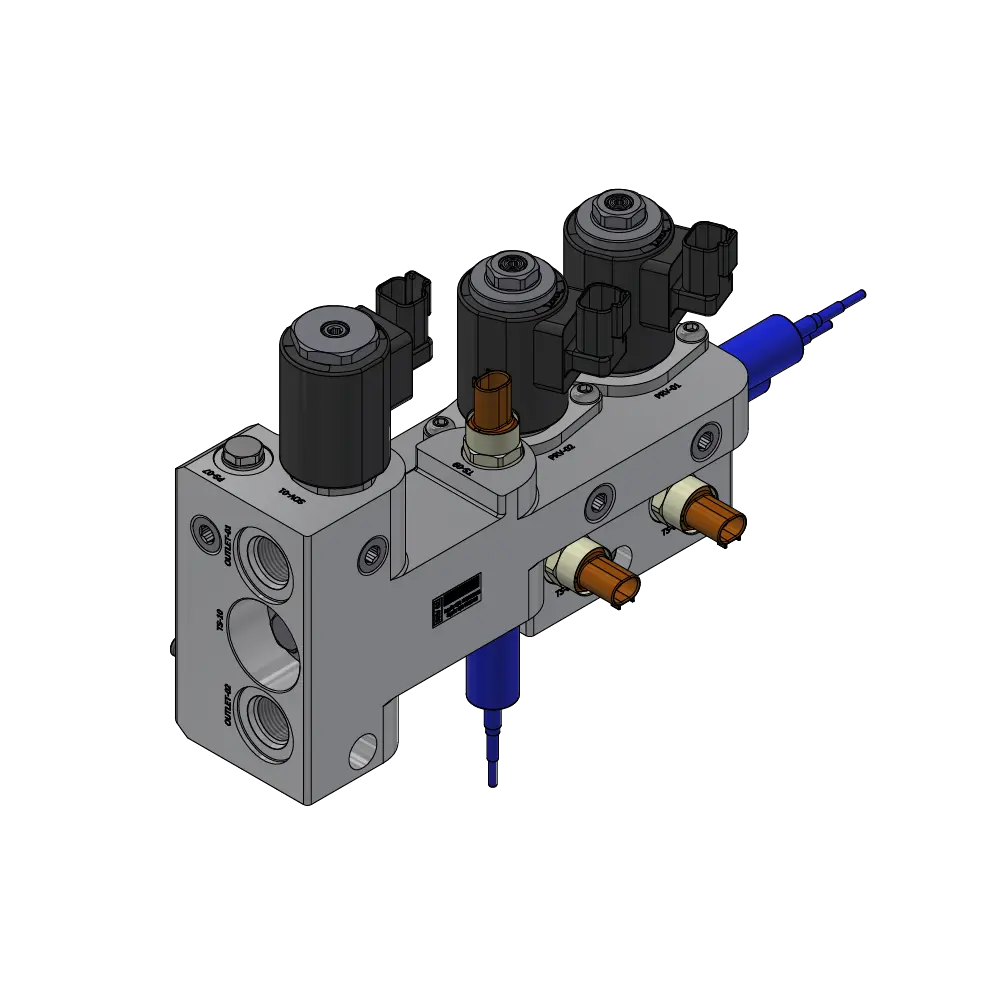

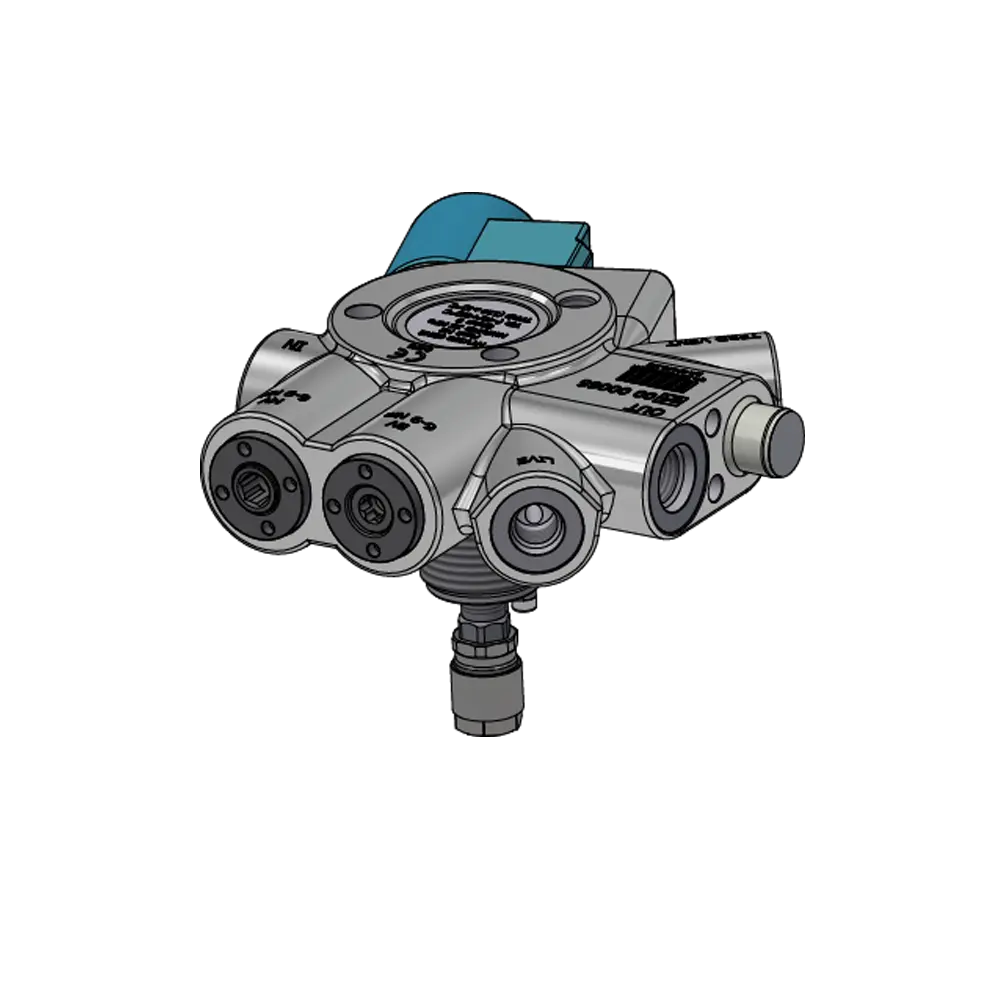

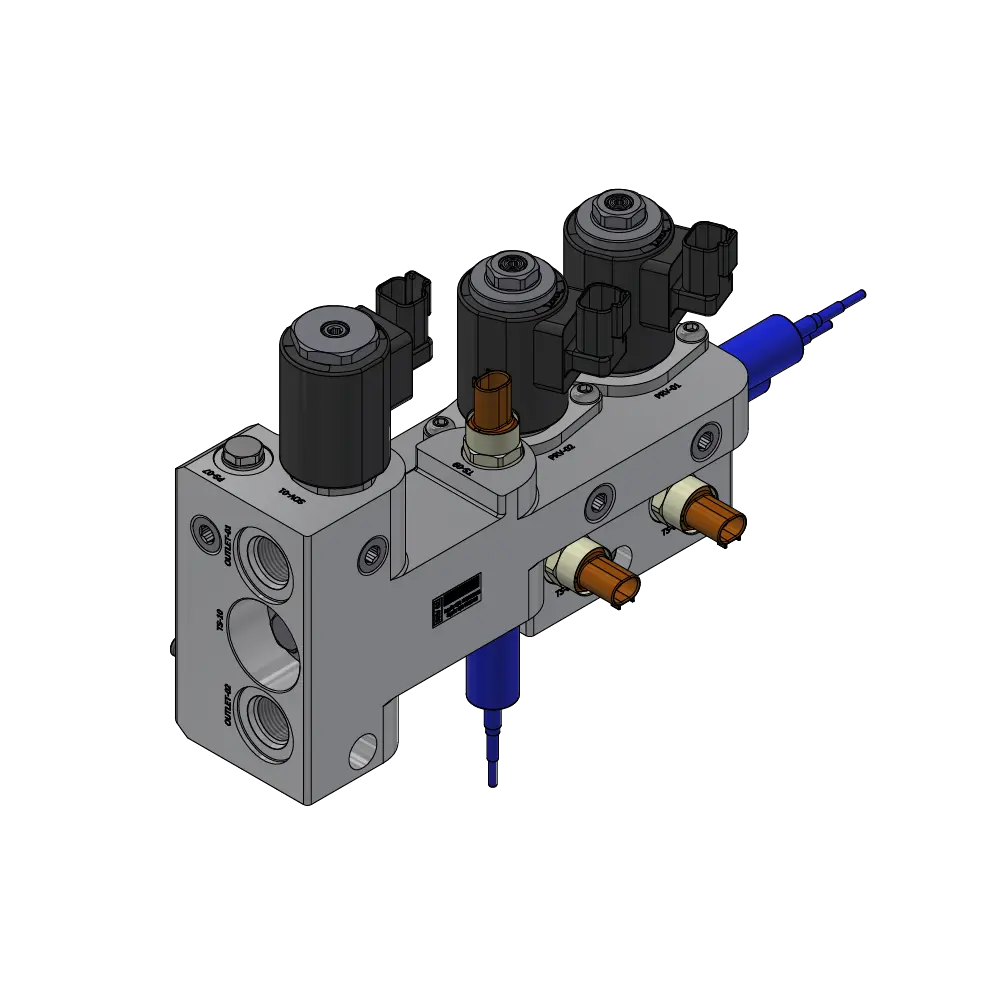

MANIFOLD

DESCRIPTION

multifunctional block that includes several functions as PRV, SOV, check valve and sensors.

PRV

DESCRIPTION

solenoid valve that provide downstream flow proportional to the electrical input.

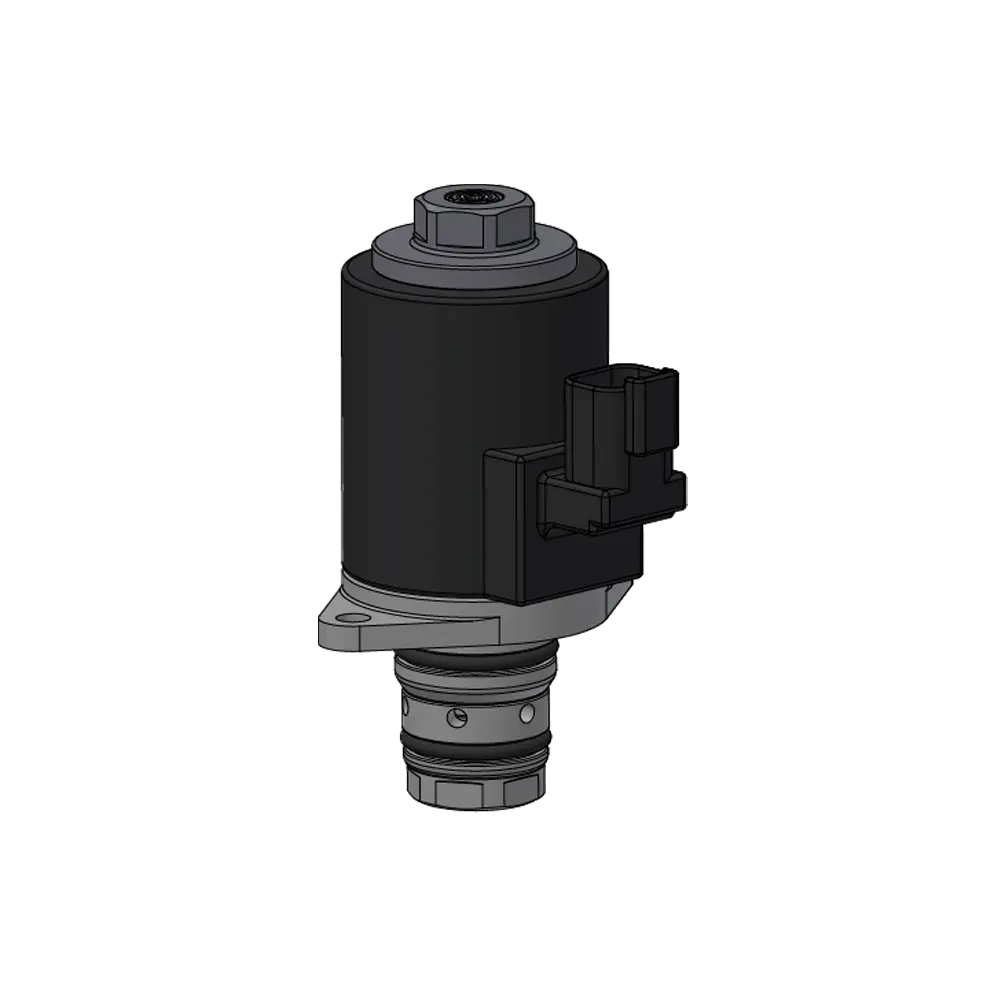

SOV

DESCRIPTION

solenoid valve normally closed.

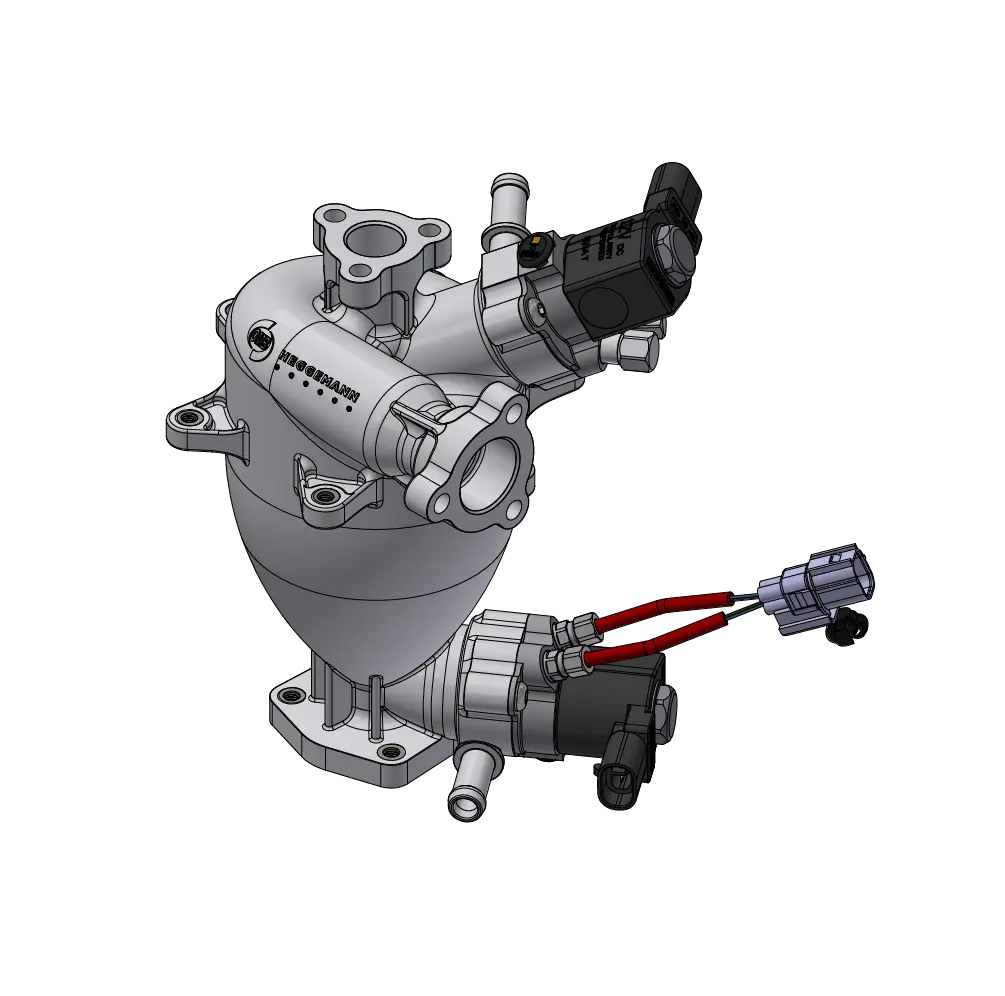

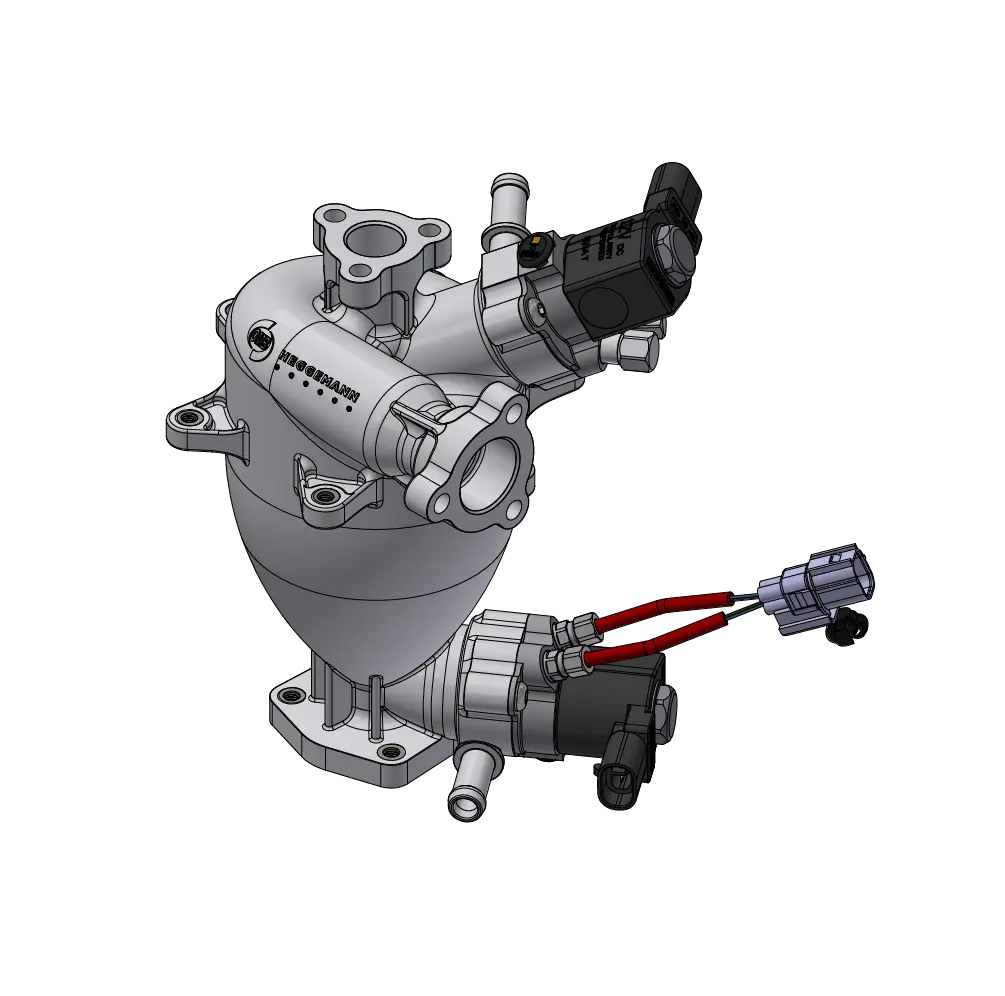

WATER SEPARATOR

DESCRIPTION

OMB has developed a water separator with anode anddrain valves and level sensor integrated.

The integration allows to the final user to have a plug and play system reducing the assembly time.

The water separator is characterized by a water separation efficiency higher than 95%.

350 HTV GEN 2

HYDROGEN TANK VALVE

DESCRIPTION

The OMB 350 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use.

FEATURES

The valve is equipped with the following components:

- Inlet / outlet single or separated

- Solenoid valve electronically controlled

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance)

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Filter 50 micron

- Excess flow valve (flow limiter)

- Temperature sensor

- Live port for pressure sensor or line middle TPRD (threaded connection directly connected to the tank)

- Pressure port (after pressure regulator)

CERTIFICATIONS

- EC79

- R134

- HGV3.1

- PED

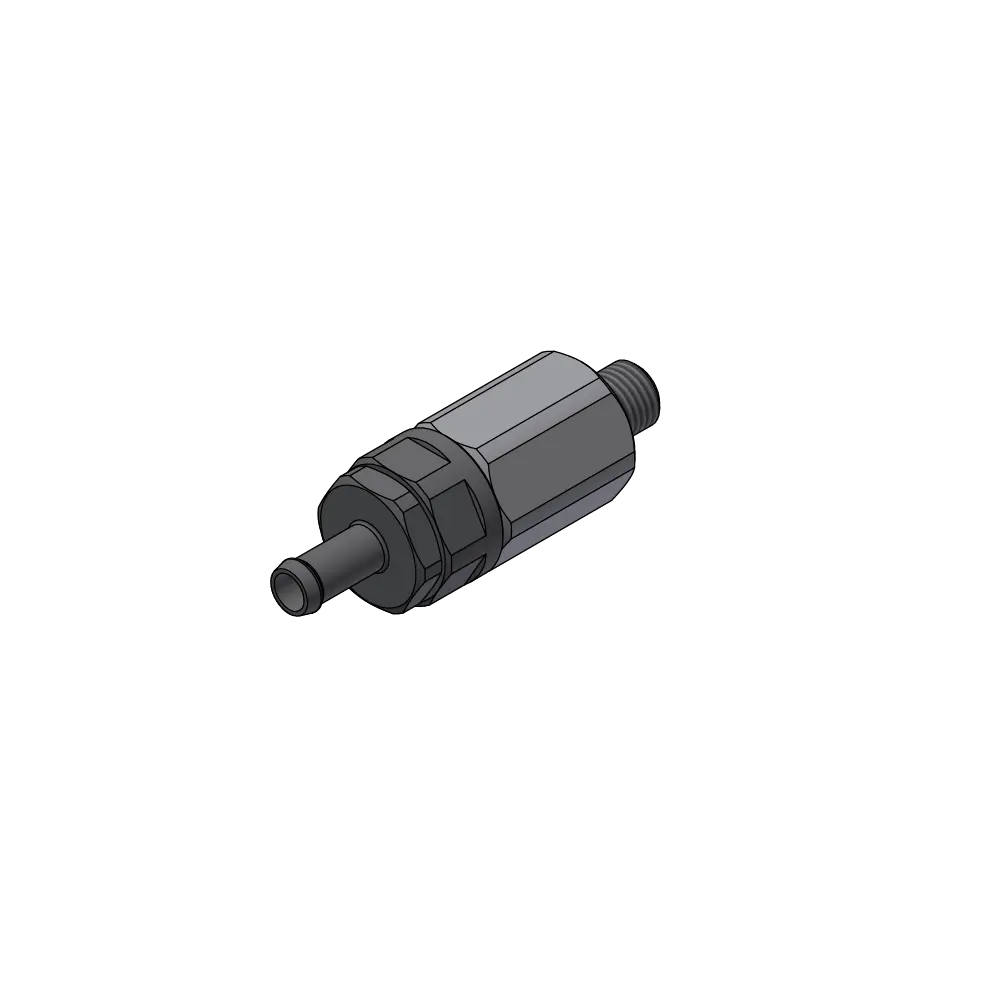

700 HCV

HYDROGEN CHECK VALVE

DESCRIPTION

- 10 Microns filter protection

- In-line check valve

CERTIFICATIONS

- EC79

700 OTV GEN 2

On Tank Valve

DESCRIPTION

OMB 700 bar H2 valve is a multifunctional valve to be assembled on a tank system, for stationary or automotive use. The valve is equipped with the following components:

- Single inlet/outlet port

- Improved solenoid valve endurance compare to Gen1

- Manual safety tap, to be used in order to isolate the automatic valve (in case of failure or maintenance);

- Bleed Valve, directly connected to the tank (in order to by-pass the excess flow, the manual valve and the solenoid valve)

- Thermal PRD (pressure relief device to prevent the explosion of the tank due to fire, based on a glass bulb concept)

- Two Filters 10 micron

- Fueling Check valve

- Temperature sensor

- Excess flow valve (flow limiter)

- Pressure Port

- Port for Middle TPRD

CERTIFICATIONS

- EC79

- R134

- EU535

- HGV3.1

- HPRD1

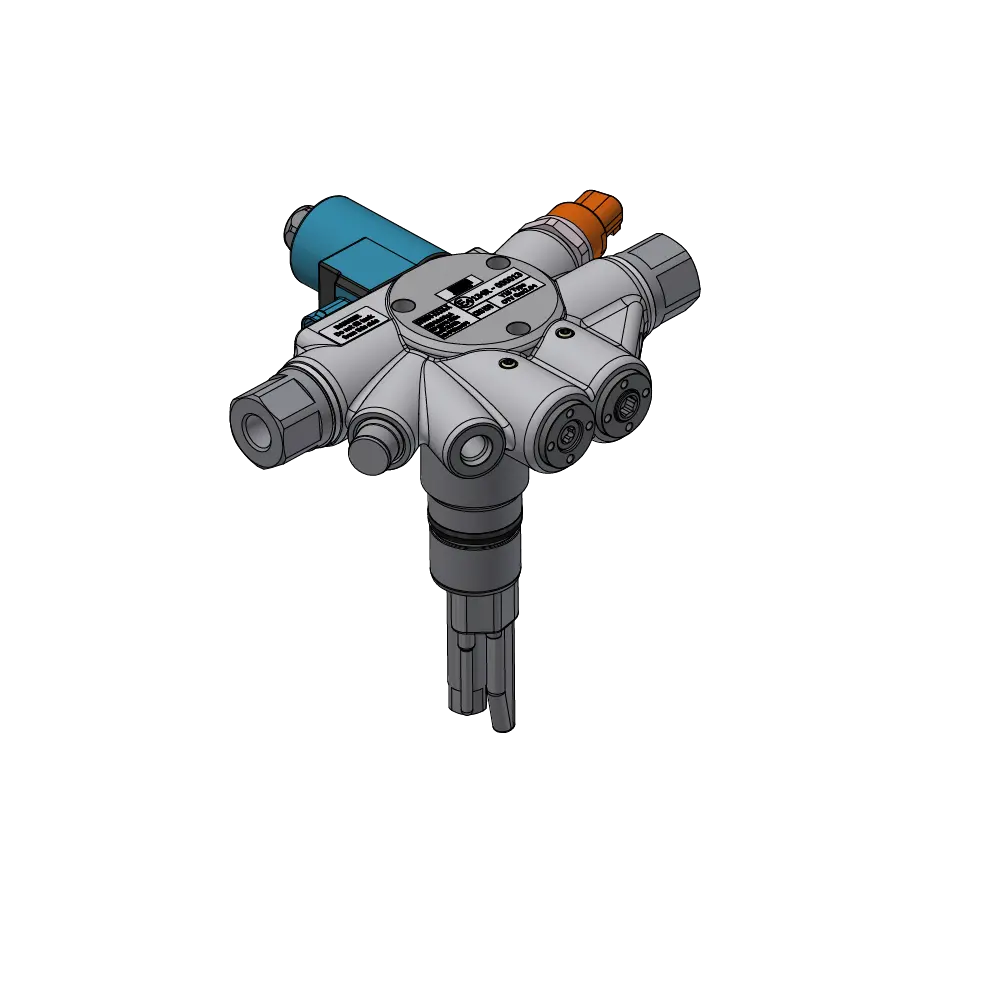

700/350 HPR

HYDROGEN PRESSURE REGULATOR

DESCRIPTION

The OMB 700/350 bar H2 Pressure Regulator (HPR) is a mechanical double stage regulator designed for fuel cell applications with the following components integrated:

- Inlet / outlet port

- Inlet Filter 10 microns

- Pressure relief valve (PRV)

- Excess Flow Valve (EFV)

FEATURES

The HPR can be requested with the following options:

- High Pressure sensors

- Low Pressure sensors (up to 2)

- Low Pressure Service Valve

- Outlet regulated pressure from 8bar to 16bar

- Inlet 700bar: Voss / Autoclave OD 3/8

- Inlet 350bar: SAEJ 1926

- PRV: customizable activation

- Possibility to install high and low-pressure sensor

CERTIFICATIONS

- EC79

- PED

COV

DESCRIPTION

mechanical valve that opens and closes under the action of the upstream pressure.

FCV

DESCRIPTION

3-way solenoid valve electrically actuated.

FIL

DESCRIPTION

Filter designed to protect the downstream items from contamination.

GPR

DESCRIPTION

mechanical single stage pressure regulator with inlet filter.

LATCH VALVE

DESCRIPTION

bi-stable solenoid valve that opens and closes upon electrical command and keep the open/close also without the electrical signal.

LPRV

LOW PRESSURE RELIEF VALVE

DESCRIPTION

The pressure relief valve is a safety component which activates in case of overpressure, venting the gas from its outlet.

MANIFOLD

DESCRIPTION

multifunctional block that includes several functions as PRV, SOV, check valve and sensors.

PRV

DESCRIPTION

solenoid valve that provide downstream flow proportional to the electrical input.

SOV

DESCRIPTION

solenoid valve normally closed.

WATER SEPARATOR

DESCRIPTION

OMB has developed a water separator with anode anddrain valves and level sensor integrated.

The integration allows to the final user to have a plug and play system reducing the assembly time.

The water separator is characterized by a water separation efficiency higher than 95%.